New football helmets could limit brain injuries

Their three layers are better than having just one

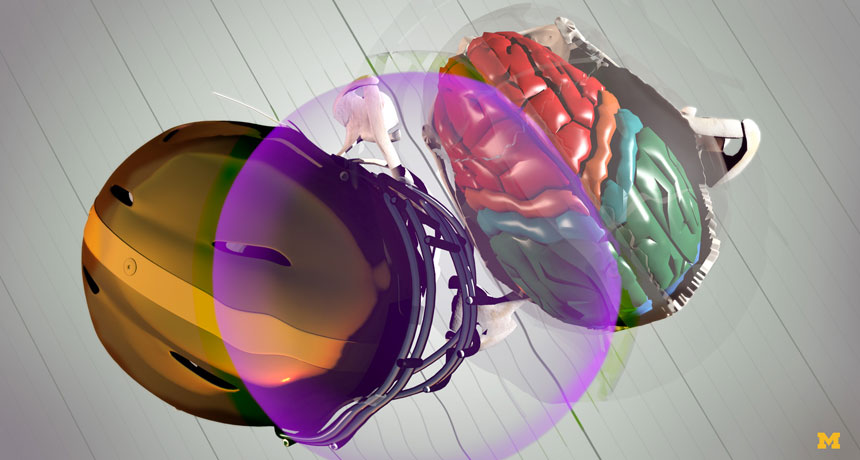

The purple area in this image represents the kinetic energy that spreads across a football player’s helmet and into the brain when head-to-head contact is made. Colors in the brain show where that energy flows as it continues to move and threaten injury.

Steve Alvey/Michigan Engineering

Two football players collide on the field. Both are wearing helmets. Still, their heads bang together, risking serious injury. A new helmet design might offer these players’ brains much better protection. Key to its advantage: three layers of energy-absorbing insulation. Most helmets today offer just a single layer.

“Current helmets do a good job of reducing the force that gets to the skull,” says Ellen Arruda. She’s a mechanical engineer at the University of Michigan in Ann Arbor. But reducing force isn’t the only problem. A blow to the head sends waves of kinetic (Ki-NET-ik) energy through the skull and into the brain. Kinetic energy is the energy of motion.

“Let’s imagine you have an egg and you hit the egg,” explains Michael Thouless, also a mechanical engineer at Michigan. Hitting the egg could crack its shell. But the impulse of kinetic energy might also send the egg flying.

Something similar happens when an athlete’s head gets hit. Even if the skull doesn’t crack, an impulse of energy travels through the skull and brain. But the brain and skull don’t always move at the same speed. So parts of the brain can crash against the inside of the skull.

Bike helmets are made to crush, or deform, on impact. That action absorbs a good deal of the kinetic energy. Afterward, however, the helmet must be thrown out. That’s not practical for football and other contact sports. And helmets for those sports do a poor job of cutting down on that kinetic energy, says Arruda.

Different layers, different functions

The team tackled the project in response to Head Health Challenge III. This competition is part of a four-year program sponsored by the National Football League (NFL), the National Institute of Standards and Technology and others. The overall goal of the program is to provide better protection from brain injuries.

The Michigan team focused first on the head, which is where the damage occurs. “We analyzed what causes the brain to move relative to the skull when you hit the skull,” Arruda explains. Understanding the movement and the factors that cause it led her team to its three-layered design.

Next the team picked out polymers. “We knew what properties we were looking for,” says Thouless. With that knowledge, the team looked through catalogs for materials to find “a combination that seemed to work.”

To sop up kinetic energy, the team chose a viscous (VIS-kus) elastomer for the innermost layer. Like elastic, this material bounces back to its original shape after something deforms it. Unlike regular elastic, however, the material returns to that shape slowly. The memory foam in some mattresses and pillows is an example of this type of material.

As the material changes form and recovers, it sheds some of its kinetic energy. This means that in a helmet, less of that energy would get through to the head. How much less depends on the specific type of polymer. It also depends on the frequency, or wavelength, of the impulse. For any particular viscous elastomer, there’s one frequency of energy that it sheds best.

However, a single impact doesn’t send an impulse with just one frequency, notes Thouless. Instead, the impulse spreads across the helmet and into the head at a range of frequencies. It’s kind of like hitting a bunch of piano keys with your fist. You’d hear a bunch of clashing notes with different frequencies.

That’s where the other two layers of the design come in. As in standard helmets, the outer two layers absorb a good deal of the force of an impact. Basically, they soften the blow.

Those layers also work together to change the group of frequencies from an impact into just one frequency. It’s a bit like an orchestra tuning up to match a single note. The frequencies bounce between those two layers. When the energy finally passes through, it’s tuned to the one frequency that works best with the innermost layer, explains Christian Franck. He’s an engineer at Brown University in Providence, R.I., who did not work on the project.

More than football players may benefit

The group’s prototype worked well. Compared to other helmets, only one-fifth of the kinetic energy from an impact made it through to the head. The team described its results in the December 2015 issue of the Journal of the Mechanics and Physics of Solids.

The design is now one of five finalists in the Head Health Challenge competition. Over the next year, the team will do more work to further improve its design. For instance, the group plans to experiment with other polymers.

Franck describes the new helmet as “a very clever design.” He also has studied how energy from an impact affects the brain. “I like the idea of reducing energy from the impact before it hits the brain,” he says. “I absolutely believe that’s the right approach.”

“This helmet doesn’t have to cost anything more than an existing helmet,” says Arruda. That means athletes at any age could benefit if they play any contact sport, such as rugby or soccer.

“The same design can be used in other applications,” she adds. For example, multiple layers could help improve the shoulder and knee pads used in some sports. The layered approach also might help make playground surfaces safer.

Ideally, the new approach will lead to fewer concussions, a type of traumatic brain injury. “The brain is a very delicate structure, and it should be protected at all costs,” says Franck.

Power Words

(for more about Power Words, click here)

biomedical engineering Combining engineering and biology to aid human health. Professions in this field develop artificial limbs, use biotechnology to produce new drugs and develop models to understand how diseases work.

concussion Temporary unconsciousness, or headache, dizziness or forgetfulness due to a severe blow to the head.

engineer A person who uses science to solve problems. As a verb, to engineer means to design a device, material or process that will solve some problem or unmet need.

frequency The number of times a specified periodic phenomenon occurs within a specified time interval. (In physics) The number of wavelengths that occurs over a particular interval of time.

force Some outside influence that can change the motion of a body, hold bodies close to one another, or produce motion or stress in a stationary body.

elastomer A material that can return to its original shape after being stretched or crushed. Natural and synthetic rubber are examples.

graduate student Someone working toward and advanced degree by taking classes and performing research. This work is done after the student has already graduated from college (usually with a four-year degree).

kinetic energy The energy held by an object due to its being in motion. The amount of this energy contained will depend on both the mass (usually weight) of the object and its speed.

mechanical engineer Someone who uses physics and materials science to design, develop, build and test mechanical devices, including tools, engines and other machines.

mechanics The study of how things move.

National Institute of Standards and Technology (NIST) A government research agency founded in 1901 as the National Bureau of Standards. Its name changed to NIST in 1988. Over the years, NIST has become a major center for research in the physical sciences. One of its enduring functions is the development of new and more precise ways to measure things, from time and electricity to the size of an atom and wavelengths of light. With facilities in Gaithersburg, Md., and Boulder, Colo., it employs some 3,400 people.

polymer A substance whose molecules are made of long chains of repeating groups of atoms. Manufactured polymers include nylon, polyvinyl chloride (better known as PVC) and many types of plastics. Natural polymers include rubber, silk and cellulose (found in plants and used to make paper, for example).

prototype A first or early model of some device, system or product that still needs to be perfected.

traumatic brain injury Damage to the brain that results from an external shock, such as an explosion, or a direct impact (as can occur in a car accident). Also called TBI, the damage can lead to either temporary or permanent impairment of thinking, memory and movements of the body.

technology The application of scientific knowledge for practical purposes, especially in industry — or the devices, processes and systems that result from those efforts.

viscous The property of being thick, sticky and hard to pour. Molasses and maple syrup are two examples of viscous liquids.

wavelength The distance between one peak and the next in a series of waves, or the distance between one trough and the next. Visible light — which, like all electromagnetic radiation, travels in waves — includes wavelengths between about 380 nanometers (violet) and about 740 nanometers (red). Radiation with wavelengths shorter than visible light includes gamma rays, X-rays and ultraviolet light. Longer-wavelength radiation includes infrared light, microwaves and radio waves.

This is one in a series presenting news on invention and innovation, made possible with generous support from the Lemelson Foundation.