How to make window ‘glass’ from wood

Researchers have figured out how to make wood transparent

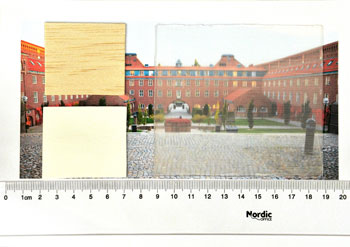

Researchers have developed a way to make wood transparent. This new material might one day find use in everything from architecture to packaging.

KTH Royal Institute of Technology

By Sid Perkins

Wood is a great building material. Strong and relatively lightweight, it’s also readily available the world over. One thing it isn’t, however, is see-through. So while it makes first-rate walls, it makes really poor window panes. But now, researchers have come up with a nifty way to make wood largely transparent.

This opens up many possible new uses for wood, researchers say. Engineers and architects could use the new material to make large window-like panels that would let lots of natural light into buildings, for example. This might cut down the need for indoor lighting during the day.

Lignin is the brownish substance in wood that makes it opaque. As a natural polymer, it’s made of many small repeating building blocks — chemical bits — that are linked into a large, chain-like molecule. Lignin, in turn, bonds tightly to the cellulose and other substances in a plant’s cell walls. That’s part of what makes wood so stiff and strong, explains Lars Berglund. He’s a materials scientist at KTH Royal Institute of Technology in Stockholm, Sweden. Materials scientists analyze how the structure of materials at an atomic and molecular level relates to their overall properties. Materials scientists also analyze existing materials and use that knowledge to design new ones.

Inspired by those results, Berglund’s group set out to make wood that was just as transparent but that didn’t lose its stiffness, as the Japanese material had.

And they succeeded. The researchers described their new transparent wood in the April 11 issue of Biomacromolecules.

The chemistry behind clear wood

The first step was removing that pesky lignin. To do that, Berglund’s team soaked sheets of wood just 3 millimeters (about one-eighth of an inch) thick in an acid bath for six hours. Thicker sheets, including some 2.5 times that thick, were bathed for 12 hours. These baths tested whether the solution would soak throughout the wood. And it did.

Lignin had started out amounting to 30 percent of the wood’s weight. After the acid bath, it made up only 3 percent. The acid did not affect the wood’s overall structure, however. Even the wood’s cell walls remained intact. On a microscopic level, the treated wood looked a lot like a kitchen sponge, with many open spaces. With most lignin gone, much of the framework that remained was made of cellulose, another natural polymer in wood.

In a two-step process, Berglund and his team then soaked the leftover wood framework in a chemical known as methyl methacrylate (Meh-THAK-ruh-layt). Also known as MMA, its molecules can link to form a clear, shatterproof material. That plastic is better known by several trade names, including Plexiglas and Lucite.

In step one, the MMA is heated until some of its molecules bond together — but are still liquid. The researchers poured this liquid onto the framework and let it soak in. To speed the process, they put everything in a vacuum chamber. That helped force the solution into the woody framework. Then they baked the material for 4 hours at 70° Celsius (158° Fahrenheit). This bonded the remaining liquid MMA into a clear solid. The new solid was a combination material, or composite (Kum-PAAZ-it).

Preventing light from bending too much

That bending of light results from a process called refraction. Every transparent material has something called an index of refraction. . For most materials, that index is a number between 1 and 2, Berglund notes. The higher the difference in index between two materials, the more that light will bend as it moves from one material to the other, he explains.

The framework’s index of refraction, however, is almost the same as solid MMA. That’s a key part of the team’s innovation, says Berglund. That near-match means that light passing through the Plexiglas-wood composite doesn’t get scattered much. So instead of appearing a cloudy white, the composite is largely transparent.

Nearly 85 percent of the light shining onto one side of a hard sheet of the composite will exit out the other side. It’s even possible to read through the material if the writing is held behind it closely enough.

Matching the index of refraction for each material in the new composite “is a very smart approach,” says Amit Naskar. He’s a materials scientist at Oak Ridge National Laboratory in Tennessee. “I like their work.”

Berglund and his colleagues think their transparent wood could be used to make big panels that replace windows. These could let lots of daylight into a building. By day, less artificial lighting — and energy — would be needed in such buildings.

But Naskar can envision other uses. Because it’s both clear and strong, the new composite can be used in the packaging industry, he says. And because the composite is about twice as strong as plain Plexiglas, it could either replace that material or help product designers use less of it. For example, something now made of Plexiglas alone could use the same thickness of the new material and end up with a product twice as strong. Or, they might use just half as much — which would weigh only half as much — and have a material as strong as the original.

Finally, Naskar notes, designers wouldn’t have to keep the composite transparent. They could dye it any color. He envisions engineers might then then use the material to make things like vehicle parts.

Power Words

(for more about Power Words, click here)

acid A chemical that releases hydrogen ions when dissolved in a solution. Acids have a sour taste and have a pH ranking of less than 7.0.

atomic Having to do with atoms, the smallest possible unit that makes up a chemical element.

cellulose A type of fiber found in plant cell walls. It is formed by chains of glucose molecules.

composites Materials made using two or more different building blocks, which together produce something with new and better features. Carbon-fiber-reinforced polymers are one example. Embedded in these lightweight, hard and strong plastics are tiny fibers made from carbon. Engineers use these plastic to build lightweight bodies for race cars and airplanes, among other things.

electronics Devices that are powered by electricity but whose properties are controlled by the semiconductors or other circuitry that channel or gate the movement of electric charges.

engineer A person who uses science to solve problems. As a verb, to engineer means to design a device, material or process that will solve some problem or unmet need.

index of refraction A measure of how light travels through a material. Scientists use the index to calculate how much light’s path will be bent as it moves from one medium to another.

innovation (v. to innovate; adj. innovative) An adaptation or improvement to an existing idea, process or product that is new, clever, more effective or more practical.

lignin A natural substance that helps strengthen the cell walls of plants. Although lignin is made from a large number of sugar molecules, which should provide energy, livestock can’t digest this material because of the way its sugars are chemically bonded together.

materials science The study of how the atomic and molecular structure of a material is related to its overall properties. Materials scientists can design new materials or analyze existing ones. Their analyses of a material’s overall properties (such as density, strength and melting point) can help engineers and other researchers select materials that are best suited to a new application.

methyl methacrylate Also known as MMA, this volatile synthetic chemical is used to make certain plastics and acrylic resins. Polymer versions of MMA also are used in making adhesives, coatings for leather and paper, inks, floor polishes, synthetic fingernails and finishes on some fabrics.

molecule An electrically neutral group of atoms that represents the smallest possible amount of a chemical compound. Molecules can be made of single types of atoms or of different types. For example, the oxygen in the air is made of two oxygen atoms (O2), but water is made of two hydrogen atoms and one oxygen atom (H2O).

opaque Unable to see through, blocking light.

Plexiglas or plexiglass The first is the trademarked name (the second is a more general name) for the chemical poly(methyl methacrylate). It’s a transparent plastic that can resist shattering. It can be used in place of glass for many applications.

polymer A substance made from long chains of repeating groups of atoms. Manufactured polymers include nylon, polyvinyl chloride (better known as PVC) and many types of plastics. Natural polymers include rubber, silk and cellulose (found in plants and used to make paper, for example).

refraction The change in direction of light (or any other wave) as it passes through some material. For example, the path of light leaving water and entering air will bend, making partially submerged objects to appear to bend at the water’s surface.

transparent Allowing light to pass through so that objects behind can be distinctly seen.

vacuum Space with little or no matter in it. Laboratories or manufacturing plants may use vacuum equipment to pump out air, creating an area known as a vacuum chamber.

wood A porous and fibrous structural tissue found in the stems and roots of trees, shrubs and other woody plants.

This is one in a series presenting news on technology and innovation, made possible with generous support from the Lemelson Foundation.