Clear, stretchy sensor could lead to wearable electronics

Researchers combine plastics and metal to make a current-carrying mesh with the best features of both

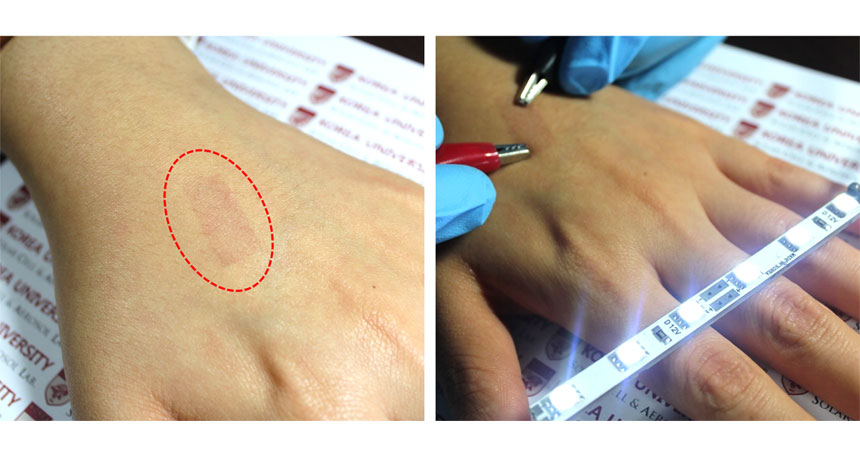

Flexible, see-through mesh of metal-covered plastic fibers (circled at left) conducts electricity and could be used in medical sensors as well as many electronic devices. Glowing LEDs (fingers at right) show the mesh is conducting electricity from the red and black clips on either side of the mesh.

An et al., Advanced Materials (2016)

By Sid Perkins

Many electronic parts are made of stiff materials that break easily. That makes them tough to use in products that need to bend, such as devices that will be attached to fabrics or glued onto skin. Now, researchers have developed a thin mesh that can both flex and conduct electricity. As a bonus, it’s largely see-through. Such a technology could have many cool new uses, scientists say.

Wearable electronics are a hot topic of research. Here flexibility is very helpful. Many such devices might also benefit from being clear. But materials that are clear usually don’t conduct electricity well. That’s because their unbound electrons, which allow current to flow, also interact with light and block it.

Sam Yoon and his team have now created a stretchable material that’s also see-through. Yoon works for Korea University in Seoul, South Korea. As a mechanical engineer, he works on developing or refining devices that move, such as machines or their parts. And the new stretchy mesh, he says, could be the basis of a wide range of new products.

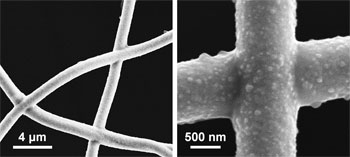

His team started out with a substance called acrylonitrile (Ah-KRILL-oh-NY-tryle). It’s a clear liquid often used to make thin plastic fibers. Yoon and his team mixed this material with another liquid, which acted as a solvent. (A solvent is something that can dissolve other substances.) Then, they squeezed the mix through a very tiny nozzle. As the mixture sprayed through the air, the solvent evaporated and the acrylonitrile molecules linked up to make long chains. (Molecules are groups of atoms bonded together to make the smallest possible unit of a chemical compound.) That linking of the molecules created a type of plastic known as polyacrylonitrile — or PAN, for short.

PAN, like most plastics, doesn’t conduct electricity. So the team’s next step would normally be to add a coating of metal so that electricity could flow through it. But such coatings typically have a tough time sticking to PAN. So the researchers added an extra step. They sprayed a thin coating of an inert metal onto the PAN. (Inert metals, like gold and platinum, typically don’t react with other substances).

The researchers then added another layer of PAN fiber atop the first, web-like layer. They provide temporary support, helping the metal-sprayed base resist sagging below during the next step.

The researchers connected the fiber-covered frame to a negatively charged electrode. Then they dipped the fiber-covered frame into a solution that included dissolved copper. The team ran an electric current through the solution for about one minute. During that time, the dissolved copper in the solution was attracted to all of the fibers. But it stuck only to those that wore a metal jacket. Besides adding a thin layer of copper that conducts electricity, this process helped bond the PAN strands together at places where they touched each other, Yoon notes.

The researchers then attached all of the fibers to a thin, clear layer of plastic. It had an adhesive backing, like a Band-Aid. Finally, the team dipped all of this into a liquid that dissolved any of the PAN fibers that lacked a copper jacket. Left behind was an open mesh of copper-coated fibers.

Because the fibers were very thin and widely separated, light waves easily travel through the mesh. Yet the copper coating acted just like a wire, permitting electricity to flow freely across it.

Yoon’s group described its conducting mesh online June 13 in Advanced Materials.

Tests showed that about 92 percent of the light that falls on one side of the mesh passes through to the other side.

“The mesh is so open, it’s easy to see why it’s transparent,” says Younan Xia. He is a materials scientist at the Georgia Institute of Technology in Atlanta, andnot part of Yoon’s team. (Materials scientists can design new materials or analyze existing ones.) To minimize any slight tinges of color added to the mesh, Xia notes, the researchers could use silver instead of copper.

Lab tests show the new mesh is quite flexible. It still conducted electricity after being bent back and forth more than 1,000 times. It also carried electricity even after being stretched to nearly six times its original length. Although the mesh as a whole was stretched and bent significantly, none of its individual fibers deformed very much, explains Yoon.

The mesh could be used in a variety of devices, his team says. Besides wearable electronics, it could find use in flexible solar cells. It could be used as a sensor in the artificial skin used on robots or artificial limbs. Or, the new mesh might be attached to the skin of a patient to monitor tiny electrical currents that nerves send through and across the skin. Adds Xia, the new material might even be used to make roll-up touchscreen displays.