LEDs offer new way to kill germs in water

New devices also could lead to bendable computer displays and more

Clean water is necessary for life. A new technology could make it easier to disinfect water and make it safer to drink.

greenaperture/iStockphoto

By Sid Perkins

Tiny wires grown on thin, flexible metal sheets can now give off an ultraviolet (UV) glow. One day, such wires might find use in disinfecting water or killing germs on instruments that had been used in surgery. These wires might even lead to bendable computer displays, scientists say.

The nano-scale wires are light-emitting diodes, or LEDs, — devices that are very energy efficient. LEDs typically glow most strongly at only a few wavelengths. Those wavelengths will depend on what the LEDs had been made from, notes Roberto Myers. He’s a materials scientist at Ohio State University in Columbus. His team developed the new LED nanowires.

The ones his group made emit UV light. Overall, UV wavelengths range from about 10 to 380 nanometers. This part of the light spectrum can kill bacteria. That makes the light useful for tasks such as disinfecting water and sterilizing surgical scalpels. (Manufacturers also use UV light to harden some plastics and dentists use it to harden dental fillings.)

The higher the energy of the UV light, the better job it does at killing germs. But it is difficult to generate light at such short wavelengths in the ultraviolet spectrum. (Those shorter wavelengths correspond to higher frequencies and thus higher energies.) The only way to generate high-energy UV radiation now is by using light bulbs that contain mercury vapor, Myers says. Large and heavy, these bulbs also need a lot of power. Moreover, mercury is toxic. So if a bulb breaks, it could poison the environment. “But if we could make UV LEDs that are safe and portable and cheap, we could make safe drinking water wherever we need it,” argues Myers.

His team built its LEDs out of a semiconductor. As that term name suggests, a semiconductor conducts electricity only under certain conditions. Myers’ team used a semiconductor called aluminum gallium nitride. The scientists sprayed a hot mix of aluminum vapor, gallium vapor and nitrogen atoms onto a thin, flexible metal surface. Everything was done in a low-pressure chamber so the elements could spread out evenly, sort of like hot spray paint.

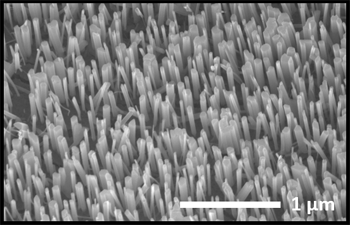

On the surface of the film, the elements reacted with each other. As they combined, they made aluminum gallium nitride. The substance didn’t make an even coating, however. It formed as a forest of nanowires. Under a microscope, this nanowire forest looked like a miniature shag carpet.

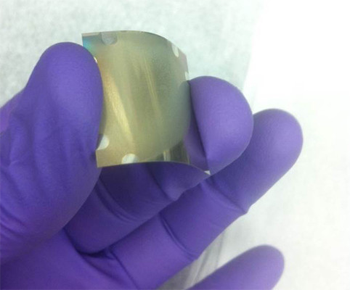

The metal onto which the forest grew is important. A thin, flexible film., it resembles the aluminum foil found in any kitchen. It is, however, about six times thicker. It also is made from a different metal. In one test, the team grew their LED forest on a film of titanium. In another, they grew those nanowires on a film of tantalum. Tantalum is a metal that doesn’t corrode easily. Myers and his team described their research in the April 4, 2016 issue of Applied Physics Letters.

“It’s very exciting to be able to grow LEDs on a flexible metallic foil,” says Lutz Geelhaar. He’s a physicist at the Paul Drude Institute for Solid State Electronics in Berlin, Germany. If scientists could figure out how to grow LEDs that glow at different wavelengths of visible light, he says, then it might be possible to create tiny bendable computer displays. He cautions, however, that “those applications are still a long way down the road.”

And flexibility might not be the system’s only benefit, notes Pallab Bhattacharya. He’s an electrical engineer at the University of Michigan in Ann Arbor. Semiconductors don’t conduct heat well. So heat released by LEDs on the surface of a semiconductor can’t easily flow away. If they overheated, that could shorten the lifespan of the LEDs. But the metal floor in these nanowire forests could shed any heat that built up from glowing LEDs, he says. That could help keep the nanowires cool and long-lasting.