How to spin synthetic spider silk

New method combines protein parts from two species to mimic spiders

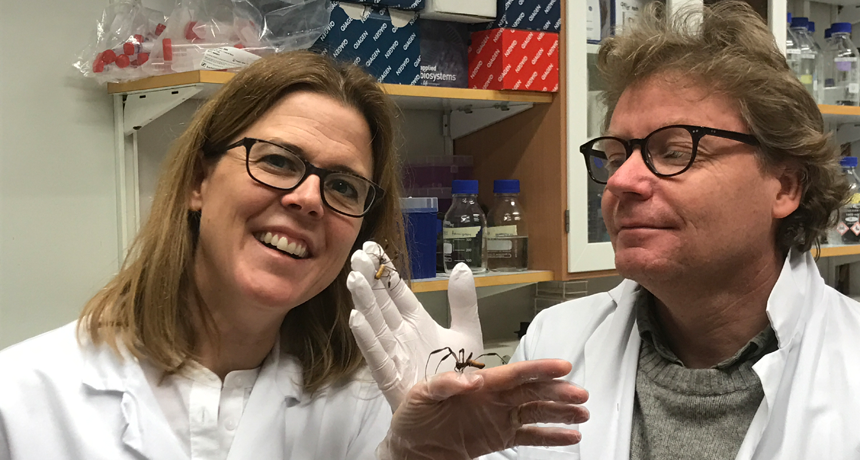

Anna Rising (left) and Jan Johansson (right) hold up golden silk orb-weaver spiders, also called Nephila clavipes, at their lab at the Karolinska Institute in Stockholm, Sweden.

Kerstin Nordling

In the comics, Spiderman hurls his spider silk at will. In real life, making artificial — or synthetic — spider silk is not nearly as easy. But researchers now have found a way to make the flexible yet super-strong strands.

“Now we can do it the way the way that spiders do it,” says Anna Rising.

She works at the Swedish University of Agricultural Sciences in Uppsala and the Karolinska Institute in Stockholm, Sweden. As a medical biochemist, she studies chemical processes important in living things. Rising initially became a veterinarian. Then she got interested in the challenge of making synthetic spider silk. It could be a big help for medicine, for manufacturing and even for producing gear to protect soldiers.

Rising teamed with up Jan Johansson, another medical biochemist at those schools. Spider silk proteins interested him because of his work on Alzheimer’s disease. In that illness, a protein clumps in the brain. Those clumps block normal brain functions and damage nerve cells. And how the proteins come together is similar in both cases.

The idea for the new process developed as the scientists studied what spiders do naturally.

Each molecule of spider silk protein is like a long chain with three basic parts. The longest part has segments that repeat over and over (which are known as “repeats”). If you look at that long part under a high-powered microscope, it would look like towers of stacked Lego blocks connected by springs, explains Randy Lewis. He’s a biochemist at Utah State University in Logan and didn’t work on the project. The Lego-stack areas provide strength, he notes. The springy sections give the material elasticity, or stretch.

A separate part of the spider silk protein is found at the start of that long portion. Another part attaches to the end. Silk proteins can hook onto each other when the silk is spun. That makes long lengths of silk fibers.

Spiders have glands in their abdomens that contain the silk-making proteins in a water-based solution. To make synthetic spider silk, Rising’s team needed building blocks that would form a similar starting protein.

Rising started by collecting fishing spiders from South Africa. (Their scientific name is Euprosthenops australis.) Then she, Johansson and other researchers studied the spider’s silk and its genes. From this, they figured out which part of the spider’s genetic code would make the silk protein. To make lots of copies of those DNA segments, they used a process called the polymerase (Puh-LIM-ur-ace) chain reaction, or PCR.

Rising and Johannsson’s group then put that genetic material into bits their DNA that would enter into bacteria easily. The bacteria added these bits to its DNA and could now make parts of the natural silk. But there was one problem. The small amounts they made were not very soluble in water. That meant the team wouldn’t be able to mix it into a water-based solution like that contained in the spiders’ silk glands.

Meanwhile, Chinese researchers did similar work with an Asian spider, Araneus ventricosus. The two groups joined forces and designed a hybrid protein. They chose the parts from each spider species that would be most soluble in water. The starting part came from the African spider’s silk. The end part was from the Asian spider. For the middle, the researchers used two repeats from the African spider. (That spider’s natural silk protein has about 100 such repeats.)

The team coached bacteria to make this hybrid protein. Then they made a solution of the protein in water, concentrated at up to 50 percent. That’s similar to the concentration in spider glands.

Getting the proteins to make fibers

Next came the challenge of spinning the proteins into fibers. As a spider’s gland pumps out the solution, the solution’s pH falls. (The pH scale measures how acidic something is. The lower the pH, the more acidic it is.) Rising’s group figured it needed to do something similar.

To mimic the way spider silk becomes more acidic as it’s spun out, the group’s new process pumps the solution through a thin tube. The diameter of the tube’s tip narrows at the end. That forces the protein solution into a jet stream. The stream empties into a beaker with an acidic, water-based solution. As the jet stream of protein goes through that liquid, its pH drops. The individual proteins then link up. This makes them fall out of the solution as fibers. The resulting strand of synthetic silk can be pulled out of the beaker and wound onto a spool or card.

The team’s study appears in the January 9 issue of Nature Chemical Biology.

Toward even stronger silk

Lewis’s group at Utah State had already managed to dissolve spider silk proteins in water. In 2015, these researchers reported making them into a silk using a different method. However, the protein level in that solution was much lower than what Rising’s group achieved.

Lewis notes that the silk protein made by Rising and Johansson’s group has only a couple of repeats. More repeats in that silk would strengthen the strands, he suspects.

Johansson agrees it might be better to have more repeats. What’s more, he thinks that keeping the protein highly soluble also is important. And the shorter repeating section probably helps with that. But silk made with their new process is already about one-third as strong as natural spider silk. Yet it has just two percent as many repeats as those in the South African spider’s silk.

The new work is important, Lewis says. “It provides an interesting opportunity for maybe simplifying the spinning process significantly.” And, he adds, if it works for large proteins, “it is a possible major advance.”

After all, raising spiders to gather natural silk is impractical. Each would have to be raised alone or they might eat each other. And there would be other challenges.

A synthetic silk could have lots of uses. “Spider silk has a unique combination of both strength and elasticity,” Lewis notes. In medicine, spider silk could work as sutures. It could repair tendons. It might help damaged nerves repair themselves. It might even form a framework for growing replacement tissues in a lab.

For the military, synthetic spider silk could go into protective gear. For instance, the strong fibers might help keep tiny fragments of explosive devices from penetrating to the skin and causing infections. In industry, spider-like silk could be used to make strong, lightweight parts for airplanes or cars. “One of the things we’ve discovered is you don’t even have to use [the silk] to make fibers,” Lewis says. The proteins could go into coatings, gels, films or adhesives.

More work must be done before this synthetic silk is ready for mass production. Yet after 13 years, Rising is glad her international team finally found a way to mimic how spiders spin their own silk. “It’s been one of the projects where everything basically just works,” she says.

This is one in a series presenting news on technology and innovation, made possible with generous support from the Lemelson Foundation.