Designing tomorrow’s burger

Can science make meat without the moo?

Scientists are exploring very different ways to produce a “ground beef” alternative for burgers. One approach grows just the edible parts of the animal. The other tries to simulate meat using plants. Shown here, Impossible Burger’s meat-free burger.

IMPOSSIBLE FOODS INC.

By Susan Milius

Today’s beef comes from animals raised on farms. So does chicken and pork. Fish? It comes from animals that live in water. But some scientists are looking to change that.

They’d like to grow just the parts we want to eat. Create burgers, for instance, without any cows. Make just the chicken nuggets and forget the rest of the chicken. Opinions differ on how best to do this. Some would start with animal cells. Others would reach for parts of plants instead. But whatever their source, the goals are the same: tasty meat for more people, less stress on the environment.

The idea of growing just the beef, not the whole cow, has been around since at least the 1890s. That sci-fi fantasy got a bit more real in 2013. That’s when Mark Post introduced his lab-grown hamburger at a televised tasting. He crafted it from what he called “cultured beef.” But the cost for that first burger was high — more than $300,000. No one expected anyone to buy a burger that cost more than a car, let alone a small plane. The idea was to show that it should be possible to grow real cow cells in a lab, without a farm or even a whole cow.

Other scientists want to make “meat” from plants. These dreamers are not looking to create a better “veggie burger.” Indeed, one of these scientists, Patrick O. Brown, doesn’t like that term at all. Veggie burgers are made from plants and have the shape of a burger. The taste is often quite different from true meat. Brown’s company, Impossible Foods in Redwood City, Calif., instead wants to make plant burgers so delicious that die-hard meat eaters will sigh happily and take another bite.

Brown’s goal: Identify those proteins or other molecules that give meats their texture and pleasing flavor. Then, track down each vital component from some nonanimal source.

When it comes to making meat, “Animals happened to be the technology that was available 10,000 years ago,” Brown says. “We stuck with that same technology. And it’s incredibly inefficient by any measure.”

Brown is convinced that science can come up with something better. His team is going the plant path. But if the “cultured” meat scientists can make their animal-cell-based dream affordable, he adds, “I’ll be their biggest fan.”

Why the push for a different ‘meat’

Many people like meat just the way it is. Yet they may not always grasp the role technology could play, says Bruce Friedrich. He’s executive director of the Good Food Institute. Based in Washington, D.C., it urges people to invent new ways of making meat.

People who love meat may not love how modern agriculture produces much of that meat, Friedrich says. Big industry can crowd animals in tight spaces. The animal’s wastes can harm the environment. And it takes loads of energy to feed, rear and slaughter livestock for meat. Change, he argues, is needed.

To be accepted, farm-free meats will have to be affordable. Maybe more importantly, they also will have to deliver on flavor. That’s no small challenge.

Hannah Laird is studying what people want their ground beef to taste like. At Texas A&M University in College Station, this meat scientist runs a sensory evaluation lab. Laird recruits beef lovers to spend six months to a year learning to pick out and score some 40 flavors and aromas that can show up in ground beef. Then for two hours at a time, her panelists sniff, taste and rate samples of beef. They score each of the flavors and aromas by comparing it to something else. For example, testers might give a mouthful of ground beef’s slight “metallic” taste a score of 6. That means it’s about as strong as the metal-like tang in Dole canned pineapples.

Raw beef is bland, Laird says. It mainly provides an aroma and flavor known as “bloody/serumy.” But cook that meat, and a whole new range of scents and flavors develop. Brown/roasted. Fatlike. Umami. Maybe smoky-charcoal — or, perhaps, smoky-wood. Or perhaps cocoa, salty, buttery, cumin or more floral flavors emerge. And for a less-than-perfect patty, testers might report “barnyard” (no surprise what that refers to).

Ground beef is so well known in America that one flavor is simply called “beef identity.”

Laird is finishing a project probing this intense culinary romance. “People say they want low-fat ground beef,” she says. In taste tests, however, when they don’t know the fat content of the meat, they’ll choose a 20-percent-fat burger over one with 10 percent fat almost every time. It all comes down to taste.

Taste preferences start forming in the womb, says Gary Beauchamp. He works at the Monell Chemical Senses Center in Philadelphia, Pa. Tests there have detected how the food that a mom eats during pregnancy can influence what her baby will like to eat on its own.

But preferences can change. People who switch to low-salt diets are often miserable at first. Months later, Beauchamp says, these diners rate the taste of their once-beloved foods as too salty. It would be daunting to predict what might happen with meat preferences, he says.

An environmental case for synthetic meat

Getting diners to reach for farm-free meat may take some doing. But scientists see a range of reasons on why it’s worth getting them to try.

“Meat production is one of the most important ways in which humanity affects the environment,” wrote biologist Charles Godfray and his colleagues at England’s University of Oxford in the July 20 Science. For instance, they point out, raising livestock leaves big environmental hoofprints.

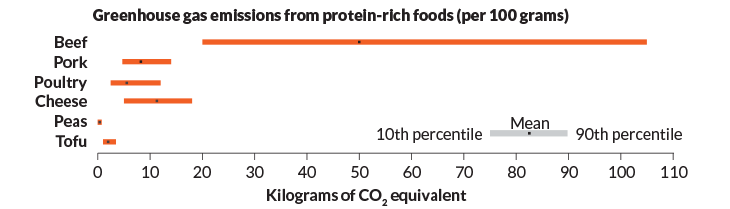

Greenhouse gases from animal farming account for more than one-seventh of all of those gases emitted by human activities. That estimate comes from a 2013 report by the United Nations’ Food and Agriculture Organization.

Scientists are still inventing how to grow lab meat from animal cells. So it’s too early to know how that might one day compare to producing lab meat. Still, a 2015 study in Environmental Science & Technology made a rough estimate. Its researchers thought that cultured meat might have less of an impact on greenhouse gases than today’s beef production does. Lab-grown meat also would require far less land. But what about the lab processes? They might use even more energy than it takes to produce beef now, the researchers said.

Worries about the environment, however, don’t inspire people to change what they eat as effectively as do concerns about health, surveys show. Americans consume an astounding amount of beef, chicken and pork. On average, each person downs 79 grams (2.8 ounces) of meat per day. That’s according to the Organisation for Economic Co-operation and Development. It’s an international group based in Paris, France. That U.S. appetite for meat, it reports, is triple the global average.

For health reasons, the American Heart Association recommends eating no more than four or five 6-ounce servings — 170 grams — each week of lean beef, skinless chicken or seafood.

No one knows how the health impacts of eating cultured meat might compare to conventional meat. After all, it’s not available in stores yet. Plant-based foods can avoid many of the unhealthy saturated fats present in most meats. But that only helps if people don’t doll up their supposedly better burgers with some saucy, cheesy extravagance. And two currently available meat-mimicking veggie options — the Impossible Burger and the Beyond Burger — are not even low in fat.

Saving calories for the planet

For Friedrich, a big reason to move away from farmed meat is the waste. “Throwing food away is a horrible idea,” he says. “But that’s basically the relationship all of us enter into every time we choose to eat meat.”

Here’s his reasoning: To get one calorie of meat from a chicken means putting in nine calories of feed. And chicken is one of the more efficient meats. Why not create just the pieces of an animal that people planned to eat?

Scientists at Maastricht University in the Netherlands have already proved that this is, sort of, possible. But it’s not easy. That lab-cultured burger in 2013 required hand assembly of some 20,000 individual muscle cells. It also, remember, was very costly.

The flavor was “surprisingly close” to regular ground beef, said food-trend researcher Hanni Rützler of Vienna, Austria. Beet juice was permitted for pinkness (that early burger hadn’t grown enough of the protein myoglobin (MY-oh-gloh-bin), which gives meat its color).

But that burger was better than the first lab-grown meat eaten in public. It wasn’t even beef, but frog-muscle fibers. They had been grown in France as part of an art project in 2003. Artists Oron Catts and Ionat Zurr created a temporary lab as part of a show in an art gallery. When the show ended, Catts and several guests sat down at a dinner table to taste the small bit of meat that they had grown.

Three tasters spit it out. The flavor was fine, Catts says. It had been served with a very good sauce of lemon butter and garlic. The muscle cells, however, hadn’t been exercised as they grew. And the mesh they grew on hadn’t had time to soften. As a result, the meat had the texture of “jelly on fabric,” Catts recalls. Not good. But as its cocreator, he felt an obligation — so “I swallowed it.”

Biologists have made custom bits of living animal tissue for decades. Medical teams have used it to make cultured bladder implants for people. Experimental lung tissue has survived for weeks in pigs. But these test projects are very different from churning out tons of tasty hamburger meat for supermarkets and burger joints.

Muscling up

One of those challenges is making enough muscle — meat — to satisfy demand.

A muscle-fiber cell that has matured can’t divide in two. So to grow muscles, researchers need to start with immature cells. The most flexible ones are stem cells. They can grow into lots of forms and divide many times.

Yet such pluripotent cells can be trickier to control than cells already on their way to becoming muscle. These appear naturally in animal muscles and are ready to repair damage. But they can’t divide as many times as stem cells can. So meat growers have to return to their cell banks for raw materials more often.

And a tasty morsel of meat contains more than muscle fiber cells. Connective tissue holds those fibers in place. Fat cells, a big component of flavor, power the fibers’ actions. One big challenge for growing any tissues in the lab has been getting blood vessels to reach into them. Without vessels to supply oxygen and food to inner cells, a scrap of muscle cells can’t develop much thickness. Thus, lab-grown meat has so far ended up as shreds. It’s ground beef, not some firm, thick steak.

Even growing jumbles of cells as a first step toward ground meat is hard. “We know that many of these cells don’t really like … to be isolated,” says Chris Dammann. He’s a cell biologist. He also cofounded a cellular aquaculture company — BlueNalu — in San Diego, Calif. As normal tissue forms, cells talk to their neighbors. Cells need to “know exactly where they are,” he says. When a scientist pulls some out to grow in a dish, the cells can “get a little bit confused,” he says. If they don’t find their bearing, they can die from a built-in self-destruct program.

Building communities

To coax confused single cells to grow into neighborhoods, researchers are exploring various types of scaffolds. Like the foundation for a house, this serves as the material on which the cells can begin to build communities.

Andrew Pelling is a biophysicist in Canada at the University of Ottawa. He has tried making scaffolds from fruits and vegetables. Working with apple tissue, his lab stripped the living insides from cells. That left a fine mesh of cellulose (SEL-yu-loass). Then he grew cells on that cellulose (although human cells, not for food). New Harvest, a foundation in New York City, gave money to test similar scaffolds from Asian pears, carrots, rose petals, asparagus and mushrooms.

Cells need more than a scaffold, however. To regulate their growth, they also need food and other materials. Scientists often give cultures what’s known as fetal bovine serum. It’s blood plasma collected from calf fetuses. A liter may cost hundreds of dollars.

That’s too pricey to use in making tons of lab-grown meat, cautions Jean-François Hocquette. This Paris-based researcher works for the French National Institute for Agricultural Research. During a Skype call, he opened with a cheerful smile. Then he gave a very gloomy view of how hard it’s going to be to make cultured meat affordable. Serum isn’t the only problem.

To grow a lot of meat, scientists need big chambers known as bioreactors. Food and other vital materials need to reach all the cells in those vats. Companies tend to keep their science achievements secret. A team funded by New Harvest, however, reported it had made a prototype cell-growing vat that was only about as big as a portable space heater. Afterward, “We were bombarded by people wanting to pick our brains,” recalls Erin Kim, who worked for New Harvest. All that fuss made her think bioreactor design might still be in its infancy.

Despite obstacles, interest in cultured meat is growing. Food scientist Liz Specht works for the Good Food Institute. In 2016, she knew of six companies chasing this dream. By late 2018, she could count at least 20. Plans for cultured products include beef, pork, seafood, poultry, egg whites without eggs, milk without cows and pet food. They also are looking to produce leather and spider silk.

The plant path

Brown at Impossible Foods is among pioneers taking a leap of faith in the opposite direction: trying to re-create meaty eating from plants.

“When I go to meetings that are basically nothing but ardent environmentalists, they’re pretty much all having meat for dinner,” he says. Even they find it very hard to change their eating preferences.

Brown is trying, however.

This molecular biologist ditched a very successful science life at Stanford University to start a burger business. “I loved what I was doing,” Brown says of his university days. But he later decided that “the most important scientific problem in the world was figuring out what makes meat delicious.” Answering that question might open the way for creating better substitutes from plant ingredients.”

Seven years ago he launched Impossible Foods. Today, he is convinced that he’s found one of the important ingredients that makes meat taste “unlike anything else on Earth.” It’s heme. Think of heme as a molecular cage made from nitrogen atoms surrounding an iron atom. In biology, heme plays a lot of roles. Among them: It forms the business end of the oxygen-carrying protein in human blood.

Brown has turned to heme in soybean roots. Instead of harvesting roots, though, this burger-maker puts genes to make the heme-like compound into yeast. He then lets the yeast cells brew the magic ingredient in vats.

The first tries weren’t so great. But repeated experiments have changed that. Some burger restaurants now serve the product. And he uses what he’s learned from one experiment to guide each next attempt at a better burger.

“However good it is today,” he says, “the next day it will be better.” In contrast, “The cow is not improving at all.”