Analyze This: This material for 3-D printing is made by microbes

Engineered bacteria ooze out proteins that link up to make ink

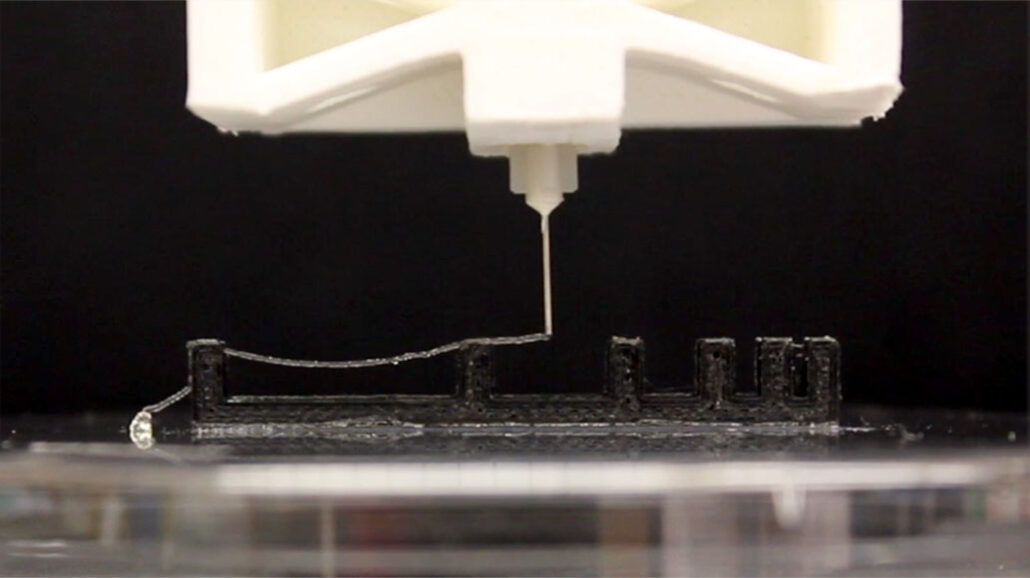

A 3-D printer squirts out a stream of ink made by bacteria. Those bacteria are engineered so that they ooze proteins that link up to form the ink. Scientists have used microbes to make drugs and chemicals for decades. But only recently have they turned bacteria into mini material-making factories.

A.M. Duraj-Thatte et al/Nature Communications 2021 (CC BY 4.0)

Researchers have made inks for 3-D printing from microbes and the goo they exude. Squishy and a bit wet, the inks feel like Jell-O. And some of them are actually alive.

For decades, scientists have put bacteria to use pumping out drugs, chemicals and fuels. But only recently have researchers modified bacteria to turn them into tiny factories for raw materials, says Anna Duraj-Thatte. A bioengineer at Virginia Tech in Blacksburg, she’s part of the team behind the new microbial inks.

Duraj-Thatte and her colleague Avinash Manjula-Basavanna did this work while at Harvard University in Cambridge, Mass. Their team modified a common type of bacteria called E. coli. The scientists tweaked genes in the E. coli to modify protein fibers the bacteria make and exude into their environment as a goo. These proteins and other molecules form a structural support for the bacteria — akin to a nest.

For one group of E. coli, the altered genes added a structure the scientists called “knobs.” In another group, a different modification caused the fibers to have a structure nicknamed “holes.” When both types of modified E. coli were grown together, both types of fibers were made. The holes acted like sockets for the knobs. And when knobs and holes latched together, the proteins formed a web that made the goo stiffer.

The team filtered the mix, removing the microbes and the nutrient mix that feeds them. That left a wet gel — a hydrogel — containing the fibers. The team tested this material to see if it would work for 3-D printing. This kind of ink needs to flow like toothpaste when squeezed. They also tested the ink’s rigidity and how much force it took to deform it.

The scientists added microbes back in to some inks. With living cells, those materials could gain new abilities. One ink contained E. coli programmed to make a drug for treating cancer. Another had E. coli that can suck up a toxic chemical.

This ink is too squishy for making building materials, says Manjula-Basavanna, who now works at Northeastern University in Boston, Mass. A living materials engineer, he works to mimic the simple processes used in nature to make materials. Microbes could be engineered to make harder, stiffer stuff though. And microbes might be able to help make stuff with less waste or have other advantages the researchers have yet to think up.

Bacterial ink

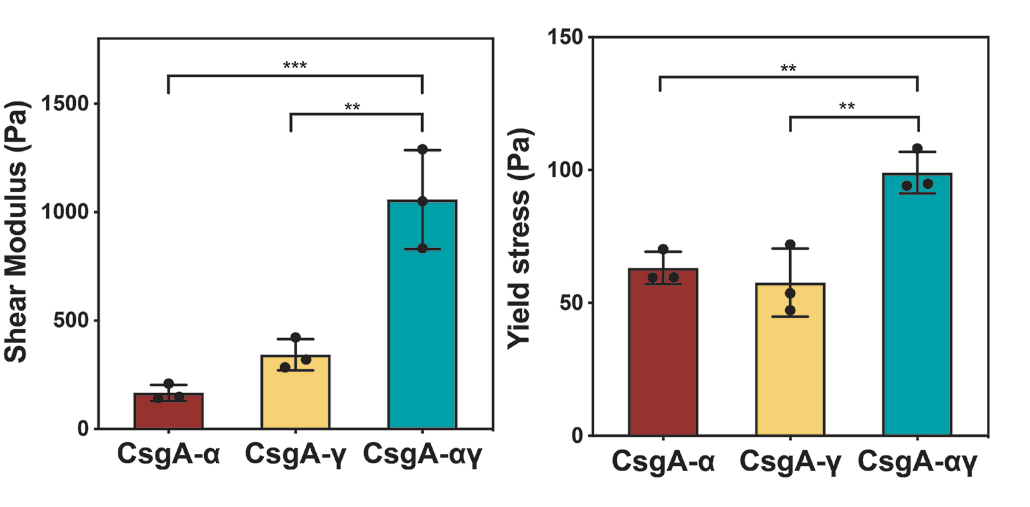

Researchers engineered two kinds of E. coli. Each kind of bacteria makes protein nanofibers. The CsgA-α bacteria make fibers with features the scientists call “knobs.” The CsgA-γ bacteria make fibers with features called “holes.” When both bacteria are grown together, the mix contains both kinds of fibers. The knobs and holes latch together, forming a structure that is like a web or mesh.

In these bar charts, the researchers tested ink made from only the knob-fiber microbes (CsgA-α), only the hole-fiber microbes (CsgA-γ) or both microbes together (CsgA-αγ). The left graph shows a measure of these inks’ rigidity. The right graph shows the amount of force it takes to permanently stretch or dent the material. That’s a measure of a material’s strength. Both are measured in a unit called Pascals (shortened to Pa).

Data Dive:

- Look at Figure A. How much more rigid is CsgA-αγ than CsgA-α? How much more rigid is CsgA-αγ than CsgA-γ?

- Think about the structure of CsgA-αγ. Why do you think it is more rigid than the other two inks? (Hint: Reread the fourth paragraph in the story.)

- Can you think of other objects or materials that use a similar strategy for strength?

- Look at Figure B. The higher the yield stress, the greater the force needed to stretch or dent a material permanently. How does the yield stress for CsgA-α compare with that of CsgA-αγ? How does the yield stress for CsgA-γ compare with that of CsgA-αγ?

- Can you imagine ways in which this material could be used? Write down two or three.

- Many researchers are working to make materials that are biocompatible. Those materials don’t cause harm when they are placed inside the body. Those are materials that can be safely used in the human body. What are two or three potential uses of very hard, rigid biocompatible materials?

- What about materials that are soft and squishy?