Better than plywood

Two teens made a strong, waterproof building material out of things that are normally thrown away

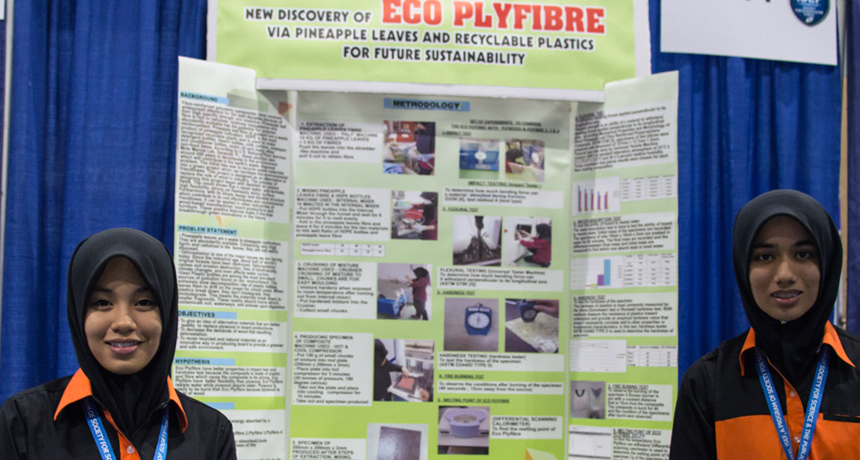

Nurul Roslan (left) and Hanis Zaini (right), both 17, invented a new material from a blend of recycled plastic and pineapple leaf fibers. It’s waterproof and stronger than plywood, according to tests by these teens from Melaka, Malaysia.

Patrick Thornton/SSP

By Sid Perkins

LOS ANGELES — A new material made from plant leaves could be replace plywood for many uses. The material is strong, waterproof, cheap and easy to make. Two teens invented it using a blend of pineapple waste and recycled plastics.

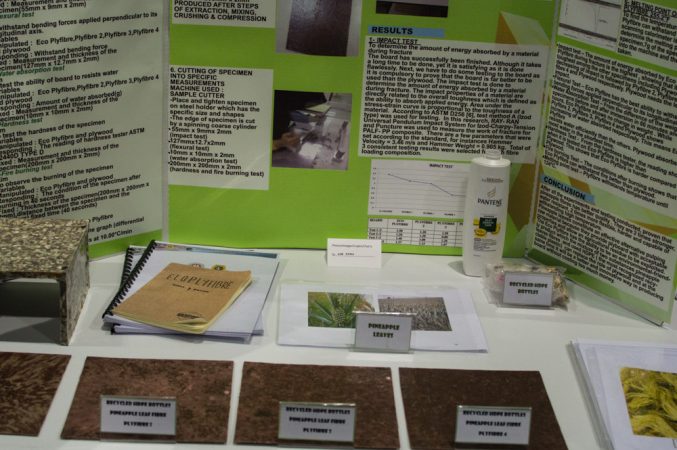

Those raw ingredients are abundant in Malaysia, where the girls live. The largest part of the new material is a type of plastic called high-density polyethylene. It is used to make many things, including milk jugs and shampoo bottles. Known as HDPE, this plastic is often recycled or thrown away, says Nurul Roslan, 17. She attends Mara Junior Science College Terendak in Melaka, Malaysia. But when treated like trash, the plastic doesn’t degrade quickly. Studies show that this plastic can take about 450 years to break down, she says.

The other ingredient in the new material is fiber from pineapple leaves. These leaves are tough because they contain a strong material called lignin. It doesn’t decompose quickly. Farmers often burn the leaves to dispose of them. That causes air pollution, says Nurul’s classmate Hanis Zaini, who is also 17. If farmers don’t burn the leaves, they send them to a landfill. There they join the discarded plastic.

Nurul and Hanis wanted to find a use for these normally discarded items. That’s when they came up with the idea to create a new building material. The teens described their technology to judges here last week. Both were finalists at the Intel International Science and Engineering Fair, or Intel ISEF. This competition was created by the Society for Science & the Public and is sponsored by Intel. Each year, Intel ISEF showcases some of the best high school science projects from around the globe. (SSP also publishes Science News for Students.)

Nurul and Hanis tested their material by molding it into large square tiles 1 millimeter thick. According to their tests, the best mix is made from 90 percent HDPE and 10 percent pineapple leaf fiber. The tiles they created are waterproof and termite-resistant. Those are big pluses in the tropical world. The material is twice as flexible as plywood but twice as strong, the teens say. Their new material is also durable, has a shiny surface and can be dyed any color. The teens expect it could be used to make anything from shelving to plastic furniture.

Best of all, Nurul and Hanis say, their material is ecofriendly. Using waste plastic and pineapple leaves could help reduce air pollution (by keeping those items out of incinerators) and extend the lives of landfills. What’s more, replacing wood-based building materials with the new material could also help reduce the need to cut down local forests.

Power words

HDPE (short for high-density polyethylene)A strong, dense plastic made from petroleum. It is commonly used to make milk jugs as well as bottles for shampoo, hair conditioner and detergent. Its recycling code number is “2”.

landfill A site where trash is dumped and then covered with dirt to reduce smells. If they are not lined with impermeable materials, rains washing through these waste sites can leach out toxic materials and carry them downstream or into groundwater. Because trash in these facilities is covered by dirt, the wastes do not get ready access to sunlight and microbes to aid in their breakdown. As a result, even newspaper sent to landfill may resist breakdown for many decades.

lignin A natural substance that helps strengthen the cell walls of plants. Although lignin is made from a large number of sugar molecules, which should provide energy, livestock can’t digest this material because of the way its sugars are chemically bonded together.

plastic Any of a series of materials that are easily deformable; or synthetic materials that have been made from polymers (long strings of some building-block molecule) that tend to be lightweight, inexpensive and resistant to degradation.

plywood An “engineered” product made by gluing thin layers of wood together into big sheets using high heat, strong pressure and glue. Because each layer — or ply — is laid down with its grain running in a different direction, plywood is usually stronger and less likely to warp than an equally thick board made from a single sheet of wood.

recycle To find new uses for something — or parts of something — that might otherwise by discarded, or treated as waste.