Cool Jobs: Scientific glassblowers shape science

Glass has played a major role in research for centuries

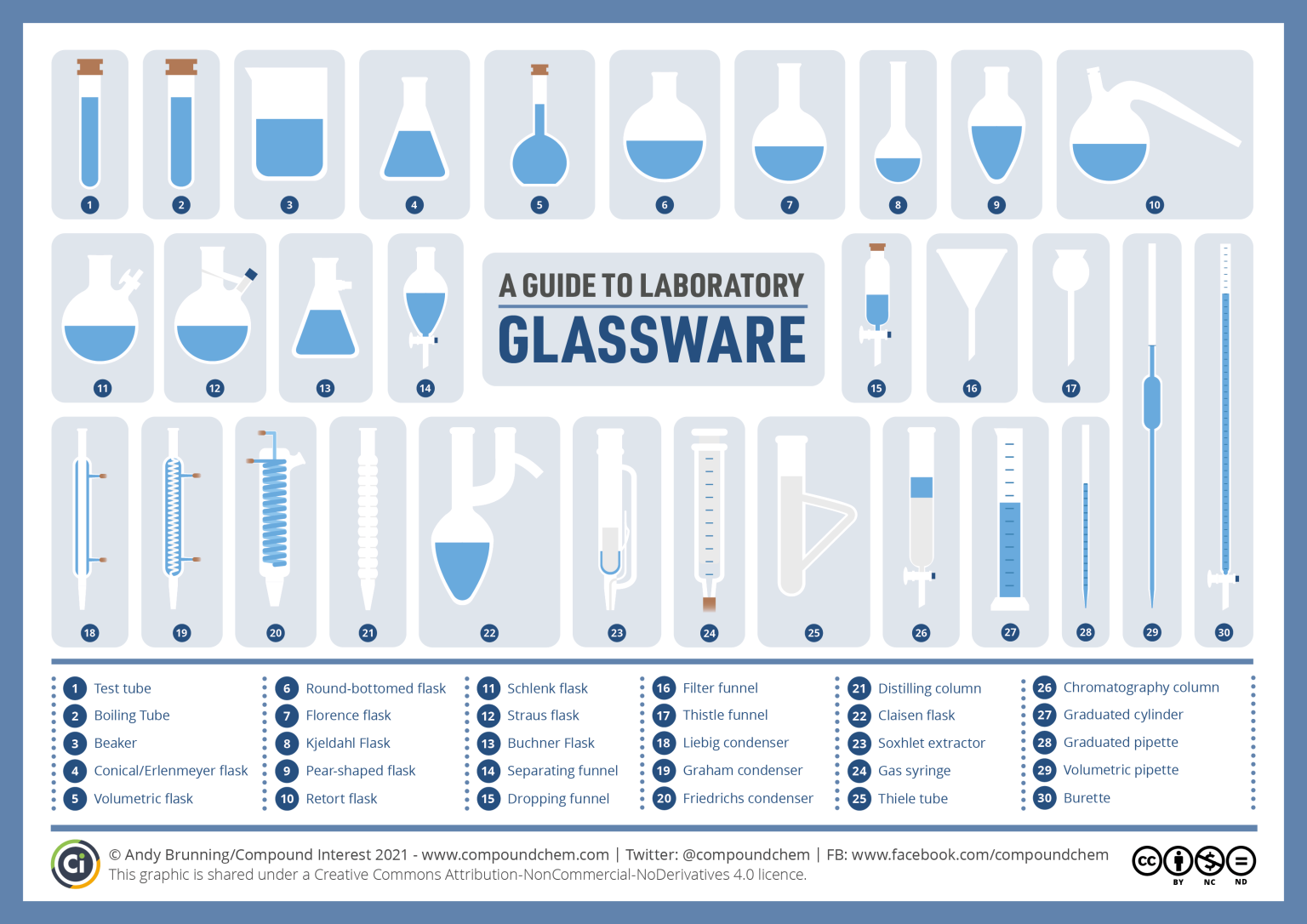

Beakers, pipettes, flasks and more. Few people realize that skilled artisans make most scientific glassware by hand (and mouth). This career truly marries art and science. Some people came to glassblowing after training in science. Others started as artists who realized their craft could help advance cutting-edge research.

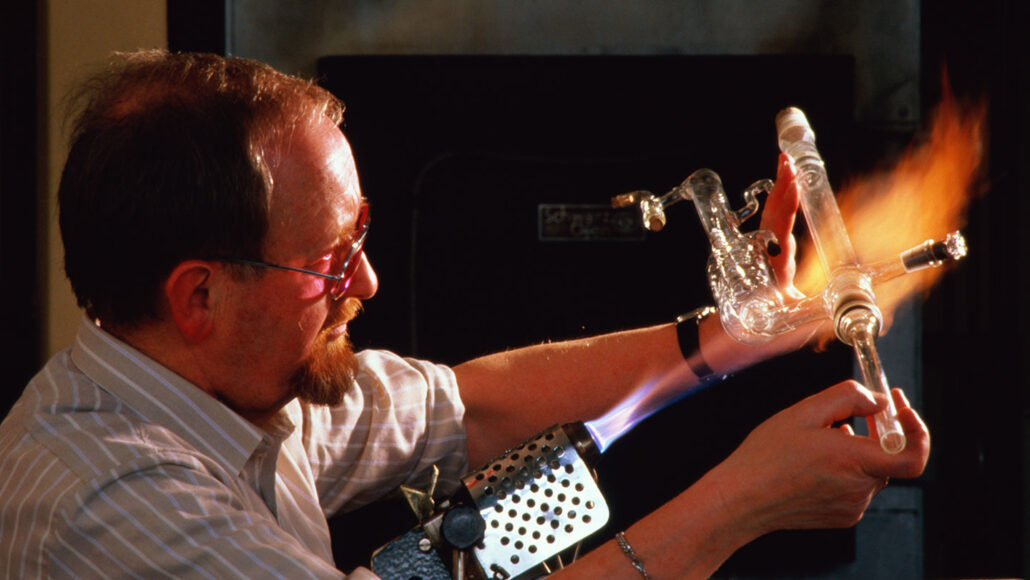

Maximilian Stock Ltd./Stockbyte/Getty Images Plus

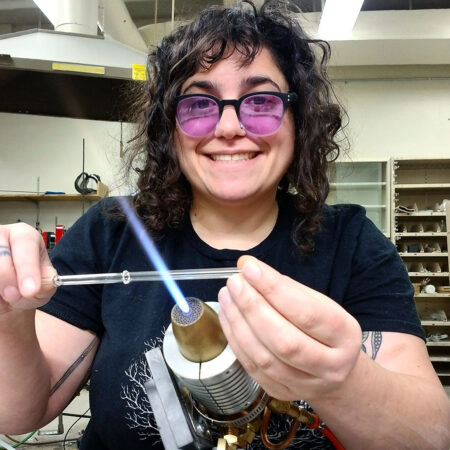

Max Daniels holds a small torch with both hands. He touches a hot, orange flame to the tip of a long glass tube. The clear, hard material turns shimmery and soft as it begins to melt. Max is learning how to make some of the glassware that scientists use in their experiments. He’s learning to become a scientific glassblower.

Glass is made by melting and chemically transforming sand. Glassblowers shape soft, molten glass by blowing air into it. People have been making glass for at least 3,500 years. Today, most do it to create art or functional housewares. For many centuries, however, some have shaped glass to make tools that have shaped our understanding of the world. Among these are the telescope, thermometer, light bulb and early photographic plates used for imaging medical X-rays, starlight and more.

“Behind many big scientific breakthroughs, there’s a glassblower that helped the scientists get there,” says Corina Guerra. She’s a scientific glassblower in St. Paul, Minn., for a company called 3M. The company also makes tape and other sticky things.

Because glass is hard and can be crystal clear, it’s “an ideal material for making observations and measurements,” notes Mike Souza. He creates glass instruments at Princeton University in New Jersey. Glass also is impermeable, so fluids and most gases can’t leak through it. Another advantage: Glass is virtually inert. That means it will not react chemically with most of the things it’s used to hold.

Without glass, we might not have science at all, argues Souza. At least not science as we know it. “Glass made it possible for early scientists to observe and perform an experiment, to measure a result,” he explains. “The scientific method wouldn’t exist without glass.”

Lessons in glass

Scientists use a lot of glass. Think about all of those beakers, flasks, test tubes and more. Even today, says Bob Russell, “About 90 percent of scientific glassware is made by hand.” Russell heads the scientific-glass technology program at Salem Community College in Carneys Point, N.J.

Daniels is a student there. He’s looking to become one of those artisans at the forefront of scientific discovery. He first learned about glassblowing in college. He was studying to become a chemical engineer. Such researchers design ways to make new chemicals and chemistry-based materials.

While taking all his classes, Daniels never thought about where the chemistry glassware he used had come from. Until, that is, he took a class on glassblowing. His instructor worked at the university, creating glassware for its researchers. “One of the things that I was most surprised to learn,” Daniels recalls, “was that most laboratory glassware is made by hand.” And some of the glassware broken by chemistry students could be fixed.

After college, Daniels decided to seek further training at Salem — the only place in the United States where graduates leave with a degree in scientific-glass technology. Daniels wants to work at a big university, one day. He hopes to make glassware that will help all types of scientists discover new things.

Creating things that have never before existed

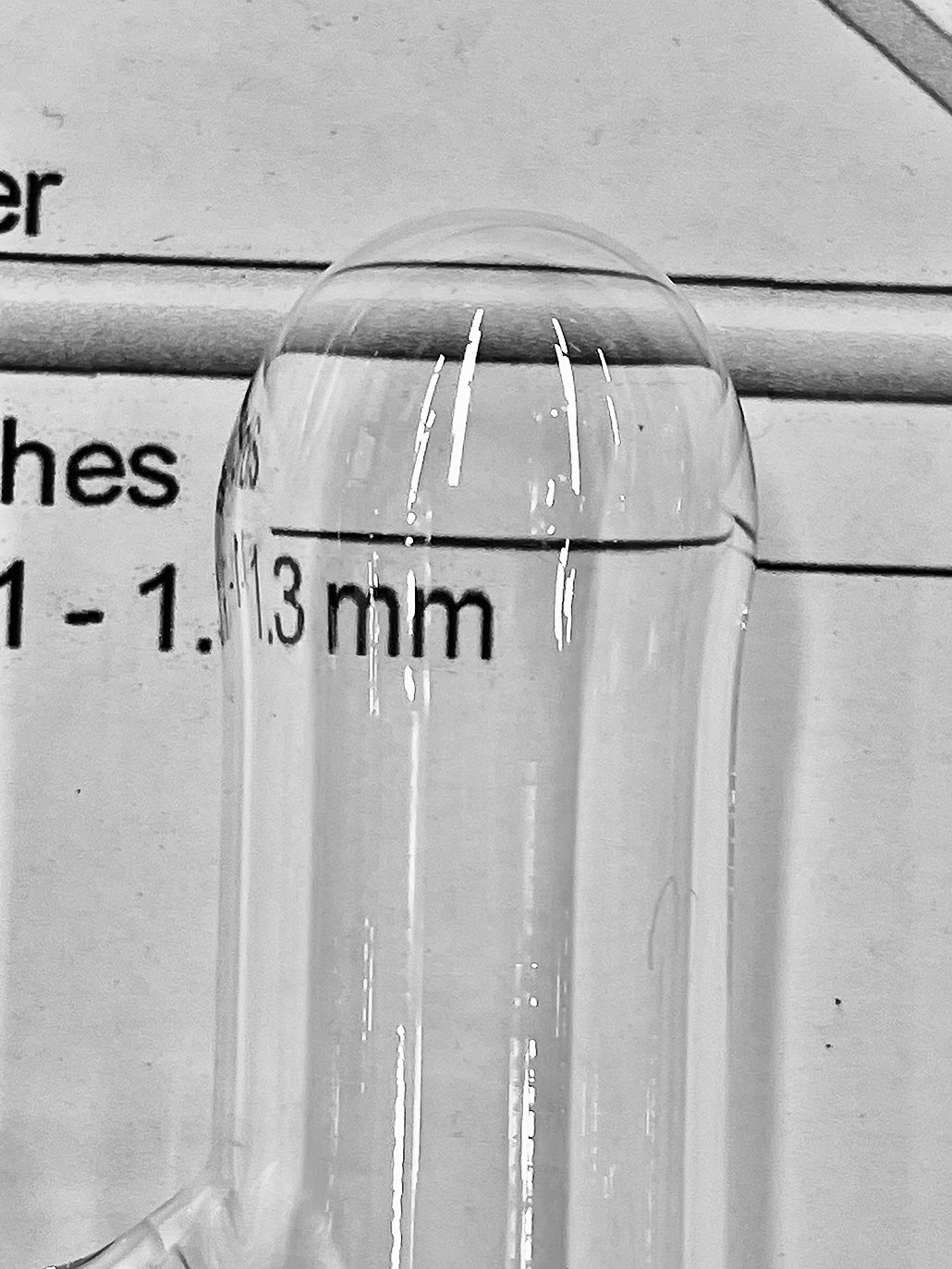

“I love getting to build stuff that’s never been built before,” says Souza. “In a way,” he says, “I get to write history.” This Princeton artisan makes specialized glass parts for an electron accelerator. These big machines rev up the motion of subatomic particles to nearly the speed of light. Then it beams them onto some target. Souza creates those targets from glass. One looks like a thin tube with a balloon sticking out of its top.

Scientists measure the direction and speed at which particles are dispersed when they hit the target. They can use these measurements to develop better tools and methods for making images of organs inside the body. They also can use these measurements to discover how matter moves through the universe.

Not all scientific glassblowers work at universities. Some work for private companies or the government. Jo Wu is a scientific glassblower at the National Institute of Standards and Technology (NIST) in Gaithersburg, Md.

“Science is fundamentally about measuring things,” says Wu. NIST is a federal agency charged with helping make sure those measurements are accurate. What is a meter? How do you define a second? How many calories should there be in a serving of peanut butter? Questions like these are what Wu helps scientists answer.

Some scientists need specialized instruments for their measurements. Many of those instruments are unique and their dimensions must be extremely precise. Such traits demand the expertise of a skilled glassblower, such as Wu. For instance, she creates pieces of glassware called optical filters that are used to calibrate lasers. “I help improve the tools so that scientists can get better at science,” she explains.

Making an impact

Some of these glassblowers started as artists. Corina Guerra is one of them. She went to college with the goal of sculpting beauty out of glass. But she found she wasn’t content making art that was just pretty. She wanted it to be useful, too. That idea strengthened when she watched a scientific glassblower make an apparatus called a Graham condenser.

Guerra stared for a long time at the tightly wound glass coils arranged perfectly inside a hollow glass tube. This device was both beautiful and useful, she realized. Chemists would use it to cool a gas, condensing it back into a liquid.

She started scientific glassblowing at a company in New Jersey called Chemglass Life Sciences. It makes glassware you might see in a school science lab. Guerra would make hundreds of flasks each day in a standard set of sizes.

She now works for 3M where she creates one-of-a-kind glass tools to aid scientists there as they create new technologies and products. “A scientist will come to my office. I’ll ask them questions about what they need a piece of glassware to do, how it will be used. We design the concept together,” she explains. And then she builds it.

There may no other item quite like it on the planet.

Guerra even has the opportunity to patent some of her scientific glass creations as new inventions. “I really like that the glass I make can have an impact on the world,” she says. “It feels good that something new can be invented or created,” she says, “because of something I made.”

Daniels is hoping that his training will similarly propel him into a scientific career. In time, he, too, might be crafting specialized instruments — to measure new types of matter, develop new medicines or even harvest energy from the sun.