Why today’s ‘fast fashions’ can be bad for the planet

The constant buy-wear-toss cycle of such clothes also costs more in the long run

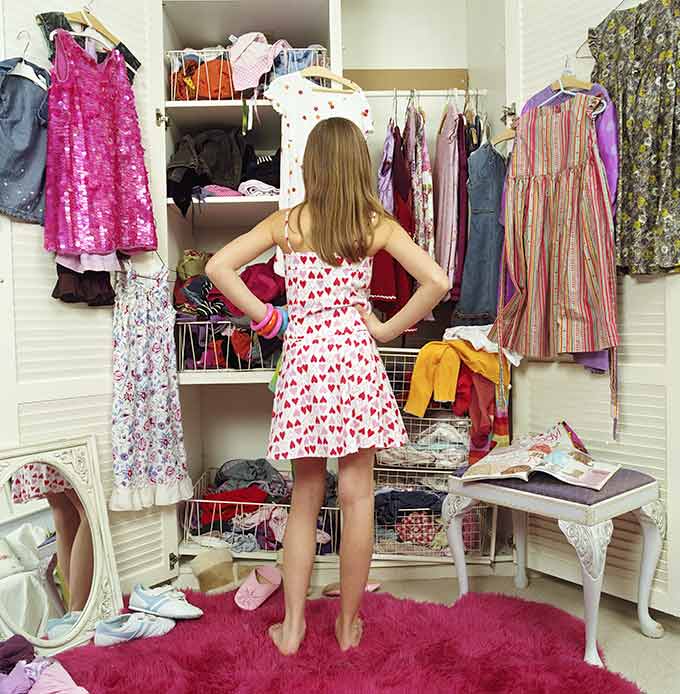

So-called “fast fashion” has made clothes affordable enough that young people can buy far more clothes than are needed. And the relatively low cost of these items also makes people likely to trash clothes when they no longer seem fashionable or may be in need of repairs.

Juanmonino/iStock/Getty Images Plus

If you’re like many teens, you probably spend a big chunk of your money on clothes. But when the COVID-19 pandemic hit this year, clothing sales fell. Now holiday sales might tempt you with deals on the latest styles. Yet many of those bargains have hidden costs for the environment — and your wallet.

“Fast fashion” refers to how the clothing industry churns out lots of relatively cheap garments and gets them to stores every few weeks. The practice lets shoppers buy new styles all the time. And garment prices are relatively low. But many of those clothes quickly wear out or go out of style. Their price tags also don’t include all of the clothes’ environmental costs.

Those impacts start when fibers for fabrics are grown or produced in factories. Pollution continues to build as clothes are fashioned from those fibers, taken to market and later laundered by users. Even tossing out those garments at the end of their useful lives has costs to the environment.

The problem starts with how we think about fashion, says Kirsi Niinimäki. She’s a fashion, textile and design researcher at Aalto University in Espoo, Finland. “Everyone nowadays owns too many garments. And we use them a really short time and then dispose of them,” she says. Even if something stays in your closet for years, you might only wear it some 40 times.

She was part of a team that looked at many studies on environmental costs of the fashion industry. That industry accounts for 8 to 10 percent of global emissions of carbon dioxide, a greenhouse gas, they found. The business also is responsible for about one-fifth of industrial water pollution. Just over a third of the tiny bits of plastic, called microplastics, found in oceans come from clothing. And people produce more than 92 million metric tons (101.4 million U.S. tons) of textile and clothing waste each year, the team found. Its report appeared in the April issue of Nature Reviews.

Fashion is a global industry, as Pietra Rivoli learned. She’s an economist at Georgetown University in Washington, D.C. Rivoli bought a cotton T-shirt in Florida. The tag said it was made in China. But, she learned, the factory got most of its cotton from Texas. And used or unwanted T-shirts often wound up in Africa. There, people sold them for reuse. She wrote about her findings in The Travels of a T-Shirt in the Global Economy. The book first came out in 2005. Since then, the African market for used tees has shrunk. More developing countries want their own clothing industries to grow. So more old T-shirts will simply be trashed.

The journey of your own clothes from fiber to finished product comes with environmental costs. Scientists and engineers have been working on ways to curb some of these impacts. They range from limiting pollution to looking for ways to ultimately recycle the raw materials that go into our clothes.

Material matters

There’s no ideal material for clothes, Niinimäki says. All fabrics affect the environment. They just do it in different ways.

It starts with the raw materials. Think about a cotton T-shirt, for example. Making it takes about 2,720 liters (719 gallons) of water. For comparison, people need at least 30 liters (almost eight gallons) of water per day for drinking, cooking and washing. That’s according to the World Health Organization. Add in cleaning, sanitation, waste disposal, farming and more, and the average need rises to 50 to 100 liters (13 to 26 gallons) of water daily. At that rate, the water for each tee could support someone for a month or two.

Wool comes from sheep or other animals. Sheep grazing can lower an area’s biodiversity. That’s the number and variety of species in a region. Where raising livestock for fibers is not sustainable, soil erosion and loss of habitats may occur.

Polyester fabrics are made of plastic fibers produced from petroleum. Drilling for fossil fuels and making the plastics releases greenhouse gases and other pollution.

Next, these fibers are made into fabrics. Manufacturing uses many chemicals. Some of them clean fibers. Others make them less likely to stain or wrinkle. Still more chemicals give fabrics a certain look or feel. Dyes then color the fabrics. All of these chemicals can pollute the environment. Some can be quite toxic.

Companies generally care more about what chemicals do than what those chemicals are. So if researchers can identify less-harmful chemicals that still work well, companies might switch, notes Sandra Roos. She’s an environmental scientist at RISE, the Research Institutes of Sweden in Göteborg.

Roos and other scientists looked at what chemicals that are used by the textile industry do. Then they used that information to create a database. It offers guidance and a checklist on their features for Scandinavia’s industry. The group wants companies to know more about the risks and impacts of chemicals over the life of a textile. Ideally, companies would then choose chemicals with less harmful impacts.

The group thinks the approach could work in other countries, too. Databases would need to be updated, though. And funding could be a challenge. The team described its findings in the February issue of Sustainability.

Dyeing for a change

Another approach is to make the processes the textile industry uses friendlier to the environment.

Most cotton is colored with dye baths. Companies “dissolve a dye, and then they dump all the fabric [in it],” says Anuradhi Liyanapathiranage. She’s a graduate student at the University of Georgia in Athens. Rinsing removes dye that didn’t bond to the fabric. Baths with more chemicals help fix, or set, the dye. “To dye one kilogram of cotton, it takes more than 100 liters of water,” she says. (That’s more than 26 gallons for each 2.2 pounds of fabric.)

Her research team came up with a new method. Instead of putting dye in a bath, it puts the dye in a gel along with tiny bits of cellulose. The texture is “something like Jell-O,” she explains. The cellulose comes from wood fiber. You’d need a microscope to see each tiny bit. But those bits have lots of surface area, so lots of dye bonds to them.

The gel goes onto the fabric as if it were an ink or paint. In all, the new method cuts water use by about 90 percent. And the team showed that the method works with a range of dye colors. Its report came out April 17 in the journal ACS Omega.

Companies also have to dispose of leftover dye. Some dyes are toxic. And even a little dye can color a lot of water. That pollution might block sunlight from reaching species that need it, explains Anthony Dichiara. He’s a materials scientist at the University of Washington in Seattle. A sponge that his group developed absorbs those dyes. It has bits of cellulose from wood pulp, plus bits of palladium, a metal. The metal speeds up a chemical reaction that turns blue dye colorless. The sponge can then be squeezed out and reused.

The altered dye molecules are still in the water. But, Dichiara points out, “in some cases the colorless form would be less toxic.” The group reported its success two years ago.

Another group invented a reusable filter to catch and break up synthetic dyes. Seshadri Ramkumar is a materials scientist at Texas Tech University in Lubbock. He and his team made this filter from a web of nanofibers. A water-repelling compound keeps the web from absorbing water. Meanwhile, the web traps larger dye molecules in its small pores. After the filter dries, a titanium-dioxide compound in it helps visible light break down the dye.

Sunlight activates the dye breakdown, notes Ramkumar. His group has tested the filter with a red dye. After six hours, eight in every 10 of the dye molecules had broken down. The rest broke down over the course of seven weeks. (Over time, dye colors can fade in visible light, but not that quickly.)

Using sunlight helps keep the dye-breakdown costs low. That matters in a competitive industry like fashion, Ramkumar says. “There needs to be a balance between technology and cost.”

He and his team just described their new filter in the October issue of the Journal of Environmental Chemical Engineering.

Manufacturing fabrics is one step. Making them into clothes is the next. Factory processes aim to minimize unused fabric. But there will be some wastes. And these still have to go somewhere.

Manufacturing also uses energy. Those processes can release greenhouse gases. Then finished clothes will move to market. This stage usually uses more fossil fuels.

Environmental impacts continue as we wear our clothes. Washing and drying laundry removes little bits of lint and dye from fabrics. Very tiny fibers from polyester fabrics are a type of microplastic. They pollute both water and air. All-cotton fabrics tend to release even more fibers than polyesters, British researchers have shown. Washing clothes in cooler water and for a shorter time can help, they suggest in the June Dyes and Pigments.

The future of fashion

Charlotte McCurdy is a designer at NEW INC in New York City. Her work spans multiple fields, including industrial design. One of her recent designs was a raincoat made from algae. She created the see-through coat to highlight the fashion industry’s impact on climate. Typical plastics in clothing emit greenhouse gases, she notes. Algae, on the other hand, can absorb carbon dioxide as they grow.

McCurdy doesn’t plan to mass-produce the coat. Instead, she’s been working on another project with fashion designer Phillip Lim. They’re designing a carbon-neutral dress. That means making it won’t add to greenhouse gases in the atmosphere. The dress will look stylish, but “it won’t be alien,” she adds, as in weird. After all, she explains, “you don’t want to feel like you’re wearing Saran® wrap.”

The bigger question is what society does beyond fashion exhibits. The answer isn’t just to go back to living off home-grown materials, such as cotton, McCurdy says. That wouldn’t provide enough for everyone, especially in developing nations. Nor can most people afford handmade clothes from fabrics like the algae-based material — at least not yet. “We need these technologies to be affordable if we want to actually make a difference,” she says.

“Maybe we could talk about repairability and end of life” before buying clothes, suggests Joanne Brasch. In other words: “What are you going to do with it when you’re done with it?” Brasch is a textile scientist with the California Product Stewardship Council in Sacramento.

“I also call myself a trash doctor,” she jokes. And in that context, her focus is on healing. More and more people are learning basic sewing skills, she notes. They fix rips and sew buttons to restore ailing clothes.

Many people also are learning how to restyle clothes that have gone out of fashion. “It’s really popular right now to do artistic mending,” Brasch says.

Secondhand shops and clothing swaps are other options. Donation programs can also get clothes to people who can use them. (Note that most charities want in-season clothes that their clients can wear right away.)

Not all ways to reuse clothing are equal. And textiles need to be reused long enough to offset the environmental costs of moving them from place to place. A team in Australia and Sweden reported this two years ago in the Journal of Cleaner Production.

Think about these things when you shop for new clothes, Brasch says. If you’re buying something in person, feel the fabric. If it feels flimsy, it probably won’t wear well. Read the label, too. Organic fabrics with low-impact dyes generally use fewer harmful chemicals, she says. Some may claim to use recycled fabrics. But don’t assume all recycled fabrics are good choices. Many of them won’t be recycled again.

“I think it really comes back to buying the right clothes and the ones that are worth mending,” she says. That means “building up your classics,” such as plain jeans or plain black pants. They won’t look as flashy as the latest fashions. But they won’t go out of style, either.

“Businesses are really clever about using the allure of fast-fashion trends,” warns Niinimäki at Aalto University. ”We have to try to avoid too-trendy looks.” Consumers should learn more about what they’re buying — and why, she adds. Are we buying something new because we need it? Or, she asks, are we buying based on our emotions?

“We should really try to be a little bit more critical about our consumption practices and try to extend the life . . . of the product,” Niinimäki says. Better-quality clothes may cost more at first. But they’ll last longer and help us look our best.

And isn’t that what we really want from fashion?