Graphene fabric keeps mosquitoes from biting

An atomic-scale layer of fabric prevents mosquitoes from getting at our blood

The mosquito Aedes aegypti (seen on human skin) transmits several dangerous diseases, including Zika. Researchers have shown that these bloodsuckers can’t bite through a fabric made of graphene.

TacioPhilip/iStock/Getty Images Plus

Mosquito bites aren’t just a nuisance on summer hikes or backyard patios. For millions of people around the world, they can bring deadly diseases. Now, researchers have proposed a new strategy to keep our skin bite-free. Add a layer of graphene to your outerwear.

Graphene is a single layer of carbon atoms. Identified in 2004, graphene earned its two discoverers the 2010 Nobel Prize in physics. Millions of graphene layers form the graphite in school pencils. Attaching oxygen atoms to graphene produces a film known as graphene oxide (GO). And that’s the basis of the new fabric.

Cintia Castilho is a graduate student in engineering at Brown University. That’s in Providence, R.I. She was intrigued when Robert Hurt, her advisor, mentioned mosquito protection at a team meeting. “Our group had used GO in clothing that protects against chemical vapors,” Castilho recalled. “From that and other applications, we knew it’s an extremely versatile material.” Yet, could it keep a mosquito from biting?

This project showed Castilho that any idea may be worth trying, even when some of your colleagues are skeptical. Her team described its success in the September 10 Proceedings of the National Academy of Sciences.

The mosquito’s unique toolkit

Castilho learned that a mosquito’s mouth consists of more than a straw to slurp up blood. In fact, there are six mouthparts. They are, in some ways, like dinnerware. “A mosquito holds your skin with two mouthparts that act as a fork,” she explains. Another four parts have knife-like serrated edges. They cut into your skin.

Only a female needs a blood meal. It will nourish her eggs. The mouthparts of males can’t penetrate skin. Some biting flies have mouthparts similar to those of a female mosquito. But none are as unique and powerful as hers.

Some female mosquitoes strongly prefer human blood. A prime example is Aedes aegypti, which transmits many dangerous diseases. They include Zika, dengue (DEN-gay) fever, yellow fever and chikungunya (Chih-kun-GUN-yah).

“We think that Aedes aegypti comes from Africa and reached other continents with our ancestors,” says Laura Harrington. People likely transported it in human-made water containers, she says. “It’s basically a domesticated animal that can’t survive without people.”

Harrington is an insect scientist, or entomologist, who wasn’t involved in the new project. She works at Cornell University in Ithaca, N.Y. The mosquito A. aegypti can feed on many mammals, she’s found. But it prefers people 98 percent of the time. During millions of years of evolution, 3,500 mosquito species have developed different body adaptations and behaviors. These help them feed on whatever animal they prefer.

Female mosquitoes transmit diseases through a channel formed by their mouthparts. They inject their saliva (spit) before pumping the host’s blood out. The mosquito’s saliva contains molecules that stimulate blood flow and prevent clotting. But sometimes that spit carries viruses from a blood source on which the insect previously fed.

We try to prevent mosquito-borne disease with protective clothing, chemical repellents, bed nets — even some drugs. But those drugs are too expensive for most people in poor countries. The same is true for vaccines. They are difficult and costly to develop. And for many diseases, they don’t even exist.

Harrington is excited about the new study because graphene-based materials are a new idea. “We’re losing the battle against infectious diseases,” she says. “Any promising new technology for mosquito protection is something we should pursue.”

Graphene oxide vs. mosquito

To test graphene oxide’s prowess, Castilho’s group needed human recruits willing to expose their arms to mosquitoes. The researchers covered a volunteer’s skin with cheesecloth, a light, airy fabric. Then they let 100 mosquitoes loose on the volunteer for five minutes. (The researchers made sure those mosquitoes were free of dangerous viruses.) A volunteer would end up with about 10 bites per square inch of exposed skin.

Then the researchers ran the test again. This time they used some cheesecloth to hold the GO film in place. After another five minutes with the insects, the volunteer would have no mosquito bites.

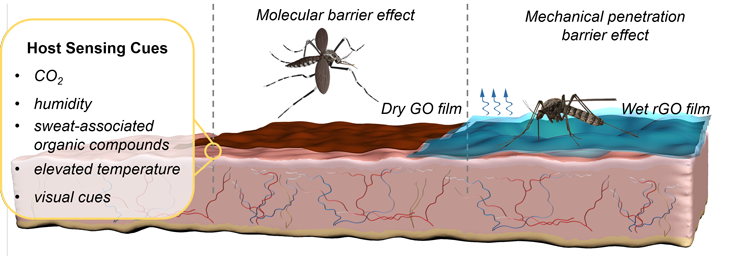

The researchers thought the film would be a mechanical barrier — like a wall. In that case, mosquitoes should still land on the arm. In fact, almost no mosquitoes landed on a GO-protected arm.

To better understand why, the researchers added water to the film. That simulates human sweat, which is known to attract mosquitoes. And now mosquitoes did land on the arm. They also were able to bite. So while dry GO was fully protective, wet GO was not. (Mosquito bites were still less frequent with wet GO than with cheesecloth alone.)

A microscope showed what happened. Wet GO has a mushy structure that makes it a less effective shield. To restore its original protection, the researchers changed GO’s chemistry. They applied a vapor to the film. That removed most of the oxygen molecules. It was now what chemists call reduced graphene oxide (rGO). Wet rGO doesn’t get mushy. And the wet rGO film kept mosquitoes from biting, even when they landed.

These results showed that wet rGO was the mechanical barrier the researchers had expected to find. Dry GO, on the other hand, blocks some (smelly) chemicals that our skin emits with sweat. These chemicals help mosquitoes find nearby people to bite. Other attractants include heat, humidity, carbon dioxide and visual cues.

Castilho is confident that rGO will work for other kinds of mosquitoes, too. The size of the mouthparts and the sensing system are very similar in all species.

Two kinds of barriers to explore

Matthew Daly is a materials engineer who studies graphene at the University of Illinois at Chicago. He was not involved in the project but is impressed by its findings. “The science is excellent,” Daly says. “And the use of graphene for mosquito control is new and timely.”

The Brown University researchers know that rGO is not a breathable material. That’s why they plan to test if other chemical changes can keep GO fully protective in moist conditions. Daly notes that one of the challenges will be finding the right chemistry. The ideal material needs to stick together while remaining breathable.

Rakesh Joshi is also impressed with the work, especially the potential of rGO. He is a materials scientist at the University of New South Wales. That’s in Sydney, Australia. “I think it’s possible to make composite fabrics with an rGO coating,” Joshi says. Composite materials contain two or more components with different properties.

Joshi thinks teaming up with textile companies would be a great next step. More research might show which graphene-based material is the best barrier. The company could help get it into clothing that’s comfortable to wear and easy to clean.

The goal is durable and affordable clothing that deters mosquitoes and protects against diseases. Future studies of the technology also may lead to products that work directly on the skin.

This is one in a series presenting news on technology and innovation, made possible with generous support from the Lemelson Foundation.