Lighting goes digital

Brighter and more efficient, LED lights are on the horizon

Computers have transformed our lives so completely that it’s difficult to remember what life was like before the digital age. But only a few decades ago, people used typewriters for writing, and calculators solved math and money issues. You couldn’t pull up an Internet browser to quickly find a random bit of information. Computers changed all that.

When it comes to lighting, though, we’re stuck in the past. The incandescent light bulb that you probably have in your bedside lamp is based on the same technology invented by Thomas Edison more than a century ago. Electricity flows into a metal filament, and the filament heats up and emits light as a byproduct.

Now, the same technology that forms the basis for our computers is set to revolutionize electric lighting as well. It’s known as solid-state lighting, and it has the potential to transform the way we use light.

Light from computers

Computer chips are made up of what are known as semiconductors. These are solid materials (such as silicon) that can carry an electrical current but, unlike regular conductors like copper wire, can also be easily turned off so that electricity will not flow through it.

|

|

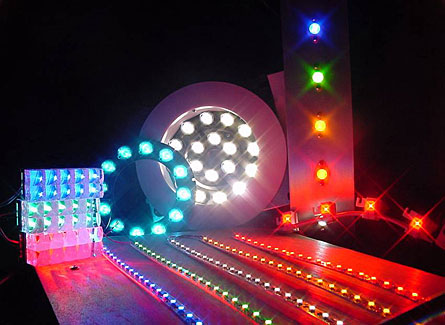

LEDs and their organic cousins, OLEDs, will one day make our homes and offices much brighter, while using less energy.

|

| RPI Lighting Res. Center |

Solid-state lighting includes two similar technologies: light-emitting diodes (LEDs) and organic light-emitting diodes (OLEDs). A diode is a simple form of a semiconductor, so both LEDs and OLEDs are like tiny computer chip parts that give off light.

Both technologies are composed of layers: one is negatively charged, and one is positively charged. When electric current flows through the diode, it excites negatively charged particles, or electrons, in one layer and causes them to fall into holes in the other layer. The energy released in that fall is emitted as light. The color of the LED depends on the material used in the layers and the distance the electrons fall.

Why LEDs?

We don’t think about it much when we flick on the lights, but keeping our houses lit uses up roughly 10 percent of all the electricity we use in homes. Add the lighting needs of businesses and the percentage is even higher. Incandescent light-bulbs are horribly inefficient: only about 5 percent of the energy goes into creating light. The rest is wasted as heat. Fluorescent bulbs are more efficient and last longer, but the toxic mercury in the bulbs means they have to be thrown out in special collections.

Depending on the color, LEDs are 20 to 50 percent efficient, so they save a tremendous amount of energy. The rest of the energy becomes heat, but they’re not hot to touch like incandescent bulbs. Researchers at Sandia National Lab estimate that within a little more than a decade, LEDs could cut the energy used for lighting in half!

LEDs also produce more than 70,000 hours of light — they last a long, long time. And they’re encased in plastic, not glass, so they’re nearly impossible to break.

These digital lights have already replaced traditional bulbs in traffic lights and in displays on clocks and cell phones. They’re used to colorfully light up bridges at night, and for larger-than-life videos, such as the enormous sign that hangs on the corner of a building in New York’s Times Square.

White LEDs are still too expensive to replace all our home and office lighting. But they make great camping flashlights, because they’re bright, tiny, energy-efficient, long-lasting, unbreakable, and can be powered by rechargeable batteries.

Many poor people around the world have no electricity in their homes, so they rely on expensive and polluting kerosene lamps. The same characteristics that make LEDs perfect for camping lights also make them ideal an ideal way to provide light for families who have never owned a bulb.

Groups such as the Light up the World Foundation have designed LEDs, powered by renewable energy, for people who lack electricity. Suddenly, children can study at night, and parents can keep working into the evening. LEDs have already improved the lives of thousands of people around the world!

The firm Kennedy and Violich Architecture created a fabric woven with tiny LEDS for a community in Mexico. It can be worn as a bag during the day, and turns into a lamp at night. (Read more about how it works here.)

New ideas in lighting

Imagine a room where you could push a button and change the color of the light. LEDs come in red, green and blue. Each one can be the size of a dot, and when those dots are combined, they can be lit up in different combinations to create an endless variety of colors. Companies have created LEDs that flow from one color to another, all through the rainbow.

“With the touch of a button you can create pretty much any color scheme,” explains Nadarajah Narendran, research director at the Lighting Research Center of Rensselaer Polytechnic Institute. “You could change the color in your room to suit your mood.”

Designers are developing new ways to use LEDs in a building. Light glows from a tile on the floor, or a panel on the wall. (This is hard to do with the breakable glass bulbs used today.) These tiles have already been built, but they don’t fit the standard systems in houses today, where bulbs get screwed into sockets. Narendran says that houses would have to be designed differently to create the right wiring for these blocks of light. He has some lighting up his lab!

But the uses of LEDs don’t end with indoor and outdoor light. Babak Parviz, a scientist at the University of Washington, is designing special lenses that use dust-sized particles of LEDs to display information. Parviz wants to create futuristic contact lenses that could sense changes in your body, such as from a disease, and notify you on the corner of the lens. These don’t exist yet, but someday you might be able to read information broadcast by LEDs literally right in front of your eyes.

LEDs, the next generation

LEDs are manufactured in the same manner as computer chips. The materials are deposited in very thin layers under extremely hot temperatures, as high as almost 1,000 degrees Fahrenheit. That costs a great deal of money. They’re also based on the material silicon, the same material that forms the basis for computer semiconductors.

|

|

OLEDs function similarly to LEDs, however, they can be manufactured much more easily; use even less power, and can be made extremely thin to be used on paper or even fabric.

|

| Yogurt6255520 / Wikimedia Commons |

Organic LEDs (OLEDs), on the other hand, have a carbon base instead of a silicon base. (Carbon forms the building-blocks of life on earth, which is why these are called “organic.”)They work in somewhat the same way as LEDs do: a current flows into the material, one layer gives off electrons, and those electrons fall into another layer. Then there’s a layer that transmits that energy into light we can see. The color of the light depends on the material in that final layer, and most OLEDs have different layers that emit different colors.

Unlike those super high LED manufacturing temperatures, OLEDs can be created at room temperature, which is significantly cheaper. Layers are deposited on a surface, as ink is layered on paper. OLEDs are also extremely thin and can be potentially printed on any substance, even paper or fabric.

“This flexibility is what makes people dream about all the different ways to use OLED technology,” says Bernard Kippelen, an OLED researcher at the Georgia Institute of Technology in Atlanta.

With OLEDs, Narendran imagines entire wall-sized sheets. He says, “You could hang one up and change lighting designs easily, like a shifting wallpaper of light design.” Because OLEDs are transparent when they’re off, a window covered by an OLED could glow brightly when night comes. Or a shimmering picture could be printed directly on a T-shirt.

OLEDs are used today in cell phone screens, but most of those other ideas are still in the design phase. Recently, though, Sony showed off the world’s very first OLED television. It’s only 11 inches large, and it costs about $2,500. It’s incredibly thin, only 3 millimeters at its widest spot — thinner than your finger from front to back — and uses about 40 percent less energy than other thin-screen televisions. The colors and picture are said to be some of the best yet. But with an expensive price-tag, and because it can’t yet be easily scaled up into a bigger screen, it may take years before you buy an OLED TV for the living room.

The path ahead

There are still challenges to overcome before solid-state lighting replaces all the bulbs in our sockets. Scientists are investigating ways to make both LEDs and OLEDs still more efficient and cheaper. The organic materials in OLEDs are fragile and don’t last as long as traditional LEDs, so scientists are looking for ways to make them sturdier. Plus, moisture harms OLEDs, so researchers are trying to figure out how to protect these lights of the future.

Kippelen says the scientists at his lab, like others around the world, are the innovators who are advancing the technology. But as for all the potential uses, Kippelen says, “I leave it to artists and designers to predict what can be done.”