Planting seeds for better plastic

Scientists are working to put the bio in plastics

By Emily Sohn

Landfills hold garbage and plastic — and the oceans do too. Traditional plastics stay around a long, long time. One goal with bioplastics is to make materials that will break down easily.

Plastic is like an annoying brother or sister: You can love it and hate it at the same time.

On the plus side, plastic is lightweight, strong and cheap. It can be hard or squishy, big or small, thick or thin. It’s the perfect material for food wrappers, eyeglasses, soda bottles, picture frames, dishes, keyboards, telephones and so much more.

On the down side, plastic contains chemicals that can harm the environment. These chemicals also threaten the health of animals, including humans.

There’s another problem, too. Plastic is made to be thrown away. But in fact it lasts for a really, really long time. And it’s piling up. Landfills and garbage dumps are full of it. There are even mounds of garbage in the oceans that cover thousands of miles. Plastic makes up a large percentage of that waste, says Eric Lombardi, executive director of Eco-Cycle, a recycling and educational organization in Boulder, Colo.

This floating trash includes all kinds of plastic. There are food wrappers, takeout containers and lots of small objects, like Styrofoam packing peanuts.

Marilou Maglione, Sea Education Association

“They get blown into the ocean, and they look like food,” Lombardi says. “Animals eat them and fill their bellies up, but they starve to death. That’s the problem. Plastic is a big culprit.”

We’ll probably never get rid of plastic altogether. But scientists are working on a new generation of plastics that are better for the environment. Some are made from natural materials, like parts of corn or sugar plants. These are called bioplastics.

Some are also biodegradable. That means that they can break down into useful materials, like fertilizer to help plants grow. Already, Earth-friendlier plastics are being used to make water bottles, gift cards, forks and more. Frito-Lay reports that it recently started selling its Sunchips brand snacks in biodegradable bags.

As the technology improves, experts hope that, some day, all of the plastic we use will be better for the planet.

Plastic has been around for more than 100 years. Over that time, scientists have found new ways to mold the material into a variety of shapes, styles, colors and textures.

Today, most plastics are made from petroleum — oil that is drilled from underground. Drilling for oil can be tough on the Earth. And turning oil into plastic releases pollution. So does burning it in cars and factories. Much of that pollution comes out in the form of greenhouse gases, such as carbon dioxide. These go into Earth’s atmosphere, trap heat and contribute to global warming.

“Consumers are aware that we need to take steps to reduce our dependence on oil and find more environmentally friendly solutions,” says David Stanton, manager of North American sales for NatureWorks, a company that makes materials for building bioplastics. Its headquarters are in Minnetonka, Minn. “We often introduce our product as: Plastic made from plants, not oil.”

NatureWorks buys corn from farmers who cultivate miles of rolling farmland in Nebraska. At the company’s milling plant near those fields, kernels get broken down to make lots of everyday products, such as oil, pet food, and feed for chickens.

For making plastic, the important part of the plant is unused sugar stored inside the kernel. The sugar is in a form called starch. To get it out of the kernels, machines cook the corn, grind it and pass it through screens.

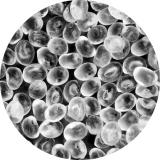

Next, microorganisms go to work. Through a series of chemical reactions, these tiny life forms (usually bacteria) turn starch (the sugar from the corn kernels) into a molecule called lactic acid. The lactic acid molecules then form rings that link up into long chains. The result is a plastic material called PLA. That stands for polylactic acid. (When placed at the beginning of a word, poly means “more than one.”) Finally, the plastic is formed into pellets. Ingeo is the name of NatureWorks’ brand of PLA.

Later, companies buy NatureWorks Ingeo and melt it into a jellylike substance. The material is stretched into thin sheets. Equipment then stamps out shapes and presses those shapes into products. Examples include food containers, laptop computers and gift cards. Ingeo can also be used to make fibers for clothes, rugs, even baby wipes.

NatureWorks calculates that making Ingeo spits out 43 percent fewer greenhouse gases compared to making traditional kinds of plastic. Making plastic out of plants also uses up much less oil.

Other companies make PLA plastic, too. And the material can be made from wheat, sugar beets and sugar cane. In the future, Stanton says, scientists will be able to use any part of any plant to make bioplastics, including the leaves. With new developments, he adds, these materials will appear in more kinds of products, from furniture to cars.

“Our next plant probably won’t use corn,” Stanton says. “There’s a lot of innovation coming.”

Break it down

It’s not just the process of producing plant-based plastics that is better for the environment. After being thrown away, these kinds of materials are supposed to have a leg up, too. Most plastics sit around for hundreds of years. But the new plastics are made to break down into dirt or just water and the gas carbon dioxide. Products don’t have to be made from plants to be biodegradable like this. Some human-made materials can break down in the same way.

But biodegradable plastics don’t always live up to their labels. Sometimes, for example, only a small fraction of a product is made from biodegradable materials. In those cases, the results are often worse. One reason is that this kind of mixed plastic can break down into especially harmful chemicals.

“You will see a lot of claims and miscommunications, saying, ‘My product is biodegradable or biodegradable in a landfill,’” says Ramani Narayan, a chemical engineer at Michigan State University in East Lansing.

“Suppose something is 10 or 15 percent biodegradable, but the 85 percent that’s remaining is not,” he says. “This remaining part has worse consequences than if you didn’t make it biodegradable. That’s the problem.”

Even if something is made only from biodegradable materials, you can’t just leave it in the sun or throw it in the trash and expect it to disappear. It won’t break down in those places. Instead, the plastic has to go to special treatment centers, called composting facilities. There, temperature and moisture conditions are just right for the material to disintegrate. The process can take weeks.

Composting facilities that do this exist in some neighborhoods, including in parts of Minneapolis, San Francisco and Boulder. People who live in these communities don’t have just trash cans and bins for recycling paper and glass. They also have a composting bin for banana peels, uneaten food and biodegradable plastic. The city takes them all away on trash day.

But most communities don’t have composting facilities. And home composting bins, which are good for turning food waste into garden feed, don’t work on plastics.

Do it yourself

Whether your city composts or not, there is one favor you can do for the Earth: Use less plastic. You can, for example, steer clear of snacks that use extra packaging, such as mini yogurt containers and small bags of crackers that contain single servings. Instead, look for bigger containers wrapped with less plastic. Even better, find stores that sell food in bulk so you can reuse your own bags and jars.

You might also try making your own stuff. And when things break, fix them yourself instead of throwing something away and buying it new, suggests Mark Frauenfelder, a writer in Los Angeles and author of Made by Hand: Searching for Meaning in a Throwaway World.

Among his list of projects, Frauenfelder makes his own yogurt and sauerkraut. He raises his own chickens. He carves spoons and spatulas as gifts out of branches that fall off a tree in his backyard. He has even tried keeping bees.

For Frauenfelder, doing things for himself started as a way to understand where ordinary objects come from and how they work. Along the way, he realized, he was putting fewer things in the trash.

“We live in a culture now where it’s a lot easier to throw away stuff that’s broken and buy new things,” he says. “It turns out that when you make your own things, in a lot of cases, the waste goes down, too.”

Power Words

bioplastic Plastics made from natural materials, like parts of corn or sugar plants.

plastic Adaptable or reshapable. Materials described as being plastics are often made from a recipe that allows them to be shaped or transformed and then locked into that shape through heating or some other processing. Some plastic materials are hard and brittle. Others, like foam or rubber-like substances, can be twisted or squeezed and then bounce back to their initial processed shape.