Recycling urine may be a way to boost plant growth

New methods recover nutrients from human pee

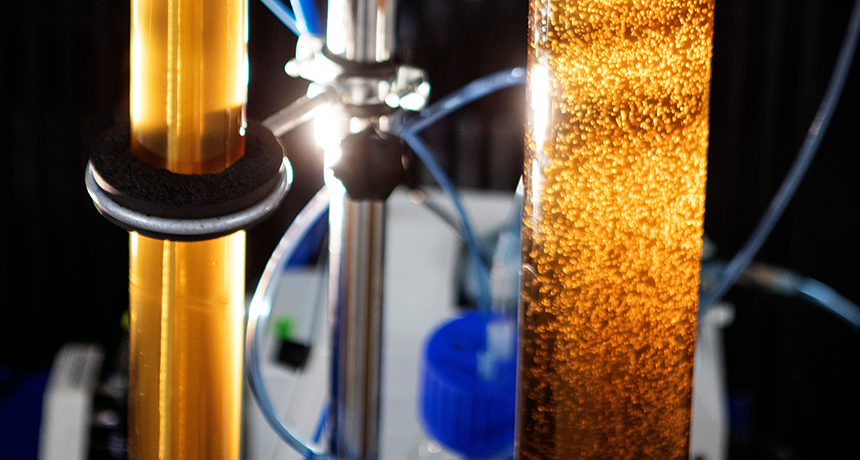

Ammonia gas separates from urine in the tube on the right. It’s part of a new process that makes fertilizer from nutrients in the waste.

Aalto University/Lasse Lecklin

Every time you pee in a toilet, you flush away potentially valuable chemicals. One day, you might not have to.

Human urine is rich in nitrogen and phosphorus. Plants need these nutrients to grow. Now researchers in Finland have a new way to pull them out of human pee. And, they say, this process can turn a profit.

Pee is mostly water. The rest of it are wastes that urine ferries out of the body. One of those wastes is excess nitrogen. Urine’s nitrogen exists mostly in the form of a chemical known as urea (Yu-REE-uh). Urine also removes excess phosphorus from the body.

Both nitrogen and phosphorus are nutrients that plants need to grow. But spraying urine directly onto farm fields is impractical. Untreated urine also can contain harmful germs that might make people sick. So researchers have been looking for ways to process pee into a safe, ready-to-apply plant fertilizer.

Surendra Pradhan is an environmental scientist at Aalto University in Finland. He got the inspiration for this innovation while doing research in Ghana. Large parts of that African country and other low-income nations have few systems for treating wastewater. Untreated human wastes can pollute bodies of water and lead to disease. Indeed, Pradhan notes, “Globally, wastewater is a very big issue.”

Methods already existed to make fertilizer from urine. One process produces crystals of magnesium-ammonium phosphate. Its common name is struvite. Growers could find it useful where they need to fertilize food crops with phosphorus and nitrogen. But farmers don’t always need both. Also, many farmers aren’t familiar with struvite, Pradhan says. So they may not buy it.

Instead, Pradhan was inspired to make a urine-sourced version of a product that is already commonly used. It’s known as ammonium sulfate. His group described their innovative approach to making this nitrogen-rich product in the May 2 issue of Environmental Science & Technology.

Two products at once

The first step in their new process adds calcium hydroxide to urine. Calcium hydroxide is an alkaline chemical, also known as a base. It increases the urine’s pH to above 12. (The alkaline range on the pH scale runs from just above 7 — which is neutral — to a high of 14.) The high pH kills any germs and sterilizes the urine, Pradhan says.

Calcium hydroxide also reacts chemically with the urine. This pulls phosphorus out of the mixture in the form of calcium phosphate. That chemical can be sold as a phosphorus-rich fertilizer. The reaction also makes nitrogen-rich ammonia gas.

The new process diverts the gas into another chemical-reaction vessel. It contains sulfuric acid. Here, the ammonia reacts with the acid to make ammonium sulfate. That’s the common nitrogen-rich fertilizer.

The researchers will continue to work on these fertilizers to see whether they contain any potentially harmful contaminants. High levels of some metals, for instance, might pose health risks. But so far, Pradhan says, his team’s research suggests the risk of harmful contaminants is very, very low.

If all works out, the new urine-recycling process should be profitable. Number-crunching by Pradhan’s group shows that recycling 1,000 liters (264 gallons) of urine could yield a profit of about €2.25, or about $2.50. (€ is the symbol for euros, and here $ represents U.S. dollars.)

To be useful, the process must make money, Pradhan explains. Without a profit, people will likely not bother to recycle urine. And that will let a lot of valuable nutrients go to waste — literally.

Håkan Jönsson is an environmental engineer at the Swedish University of Agricultural Sciences in Uppsala. He did not work on Pradhan’s project. Using calcium hydroxide to do two things at once is “innovative,” he says. And, he adds, “The total process seems to make economic sense.”

Still, Jönsson notes, the concentration of nitrogen in the fertilizer is only about 13 percent. That’s lower than the 21 percent found in commercial ammonium sulfate. In his view, then, there is still room to improve this process.

Collecting urine

To make money, Pradhan’s process needs a steady supply of urine that does not contain other bathroom wastes. The best way to do that is with a separating toilet. In this type, pee goes into one part. Feces go in another. Although still relatively rare, such toilets are becoming more common in Finland and Sweden.

Other researchers are also trying to turn human wastes into something useful. Two of Jönsson’s colleagues at the Swedish University of Agricultural Sciences are developing their own “No-Waste Toilet.” The name refers to its goal of turning human wastes into a useful fertilizer.

The Swedish team’s design uses wood ash to raise the pH of the urine. That step stops a chemical process that would have changed urine’s nitrogen-rich urea into ammonia. The wood ash stabilizes the nitrogen in urea. Now the urine can be dried without losing the nutrient value of its nitrogen. The resulting materials could be used as a fertilizer product, according to environmental engineers Jenna Senecal and Björn Vinnerås. They described the toilet in the May 15 issue of Science of the Total Environment.

Pradhan’s group and the Swedish team use different approaches. But their goals are the same — safe treatment and reuse of urine. Our bodies excrete excess nutrients from foods as wastes. Says Jönsson, “The recycling of the nutrients from our food is needed for a more sustainable society.”

This is one in a series presenting news on technology and innovation, made possible with generous support from the Lemelson Foundation.