Scientists turn toy into valuable tool for medical diagnosis

Human-powered ‘paperfuge’ separates blood components in fewer than 90 seconds

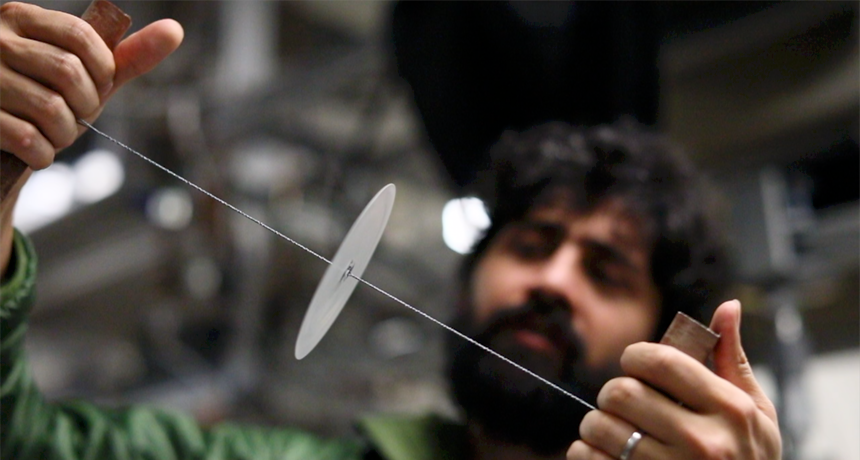

Stanford University researcher Manu Prakash demonstrates a human-powered, rapidly spinning whirligig that can separate blood into its components in just 90 seconds.

Kurt Hickman/Stanford University

By Sid Perkins

Medical lab equipment often showcases high-tech at its best. Devices can perform complicated tasks, such as separating blood into its parts, quickly and easily. But these machines often are difficult — even impossible — to use in poor countries or at remote field clinics. Often expensive and bulky, they tend to require training to use. And most are powered by electricity. But researchers have just unveiled a simple, low-cost human-powered device useful for medical diagnoses. It can separate blood into its different parts.

Best of all, it’s so simple a child could run it. Indeed, it is based on a toy that’s been around for thousands of years.

Manu Prakash is a bioengineer at Stanford University in California. There, he designs medical devices that can be used easily by anyone anywhere in the world. A few years back, his team invented a microscope made largely of paper that costs less than a dollar to make.

On a trip to the East African nation of Uganda, a few years ago, Prakash was surprised to see an expensive centrifuge being used as a doorstop. Medical labs use these devices to separate liquid mixtures, such as blood or muddy water, into their different components. Based on what they learn from those components, doctors will tailor a patient’s treatment.

But the clinic did not have electricity. So no one could use this machine.

The key part of a centrifuge is its rapidly rotating interior. Think of it as a small version of a top-loading washing machine. In a centrifuge, though, the interior chamber spins faster than the parts in a car’s engine. Anything inside a spinning centrifuge experiences a force that slings it away from the center of rotation and toward the device’s rim. This is similar to how wet clothes in the washer get squished against the inside wall of the drum during the spin cycle.

When a centrifuge spins a test tube of blood to separate out its various parts, the vial is loaded in with its base pointing outward. Rotation forces outward the densest parts of the blood — platelets and blood cells. Lighter parts, such as the fluid or plasma, stay on top. Doctors or lab technicians can then separate each layer for tests that guide treatment. Without a centrifuge, such tests become difficult, if not impossible.

The centrifuge that had become an expensive doorstop inspired Prakash’s team to invent something that could serve the same purpose. Their device would have to spin very quickly. It would have to be cheap to make and easy to use. And it would have to run without electricity.

Previously, Prakash notes, people had suggested employing kitchen devices as a low-cost centrifuge, such as an egg beater or handheld mixer. But these tools could not rotate fast enough to separate blood well. So, he and Saad Bhamla, also at Stanford, started brainstorming about what might be able to spin rapidly enough.

And that’s when Bhamla remembered a toy: the whirligig.

These are very simple. Start with a small disk with two holes in it, similar to a large button. A loop of string is passed through the holes. Then handles are placed at each end of the loop. When the string is twisted, it stores energy. Pulling on the handles releases that energy and causes the disk to spin rapidly. If made and used correctly, the whirligig will unwind and then rewind itself. Additional pulls on the handle cause the disk to reverse and spin in the other direction.

“It’s not complicated,” says Bhamla. “I can’t think of anyone of any age who can’t learn how to use it.” Indeed, Native American children had a version of this toy as early as 500 B.C. Their disks were made of clay, bone or stone. Instead of string, they used a loop of leather.

A whirligig is different than a centrifuge. It spins in two directions rather than just one. But that doesn’t matter, says Prakash, because rotation in either direction causes denser components to be slung in the same outward direction.

Prakash and his team made a few whirligigs and then used high-speed video to help measure how fast they spun. And it’s a good thing they did, says Bhamla. The smallest whirligig had a disk only 5 millimeters (0.2 inch) across. Yet it could spin at rates of up to 125,000 revolutions per minute. (The rotating parts of a car’s engine usually spin at only 2,000 to 3,000 revolutions per minute.)

“We think this is the fastest spinning speed ever recorded for a human-powered device,” says Prakash. The team described its invention online January 10 in Nature Biomedical Engineering. They also have applied for a Guinness World Record, Prakash notes.

Story continues below video

How they made it useful

A disk 5 millimeters across is far too small to hold a test tube of blood. And larger versions of the team’s whirligigs spin more slowly. But were they still spinning fast enough to separate blood?

Absolutely!

The Stanford researchers then designed a disk large enough to hold a mini test tube. It holds 20 microliters (0.0007 ounce) of blood. That amounts to less than one drop. But when spun, this whirligig separated red blood cells from plasma in fewer than 90 seconds.

The whirligig-based centrifuge was made of paper. So the researchers named it a “paperfuge,” a mashup of paper and centrifuge. Their prototype costs less than 20 cents to make, yet works as well machines that cost $1,000 or more, the engineers report. They also developed low-cost plastic versions that can be 3-D printed easily. They can spin at rates of up to 10,000 revolutions per minute.

“This is a very creative idea,” says Victor Ugaz. He’s a chemical engineer at Texas A&M University in College Station. Like Prakash, he and his team have designed techniques to do medical analyses in field clinics and other remote areas lacking access to electricity. He really likes the simplicity of the paperfuge. “Someone with very little training can use it,” he says. Plus, he adds, its similarity to a toy makes it relatable: Users “can instantly see how it works.”

The paperfuge can serve several functions, Prakash and his team note. A simple separation of blood into its parts can help doctors diagnose anemia, for instance. In that disease, patients typically have low numbers of red blood cells. A slightly more complicated technique can help doctors identify the parasites in blood that cause malaria.

Nearly half of the world’s population is at risk of being infected with that disease, which is transmitted by the bite of an infected mosquito. In 2015, more than 210 million people did pick up the disease, according to the World Health Organization. Some 429,000 of them died.

Treating many of those people is difficult since there are more than 1 billion people around the world that have no access to roads or electricity, says Prakash. With the paperfuge, the separation of blood to isolate the malaria parasite takes just 15 minutes. That’s about the same time needed to isolate the parasites from blood with a regular centrifuge.

This could be a game-changer, he now argues. “I realized that if we wanted to solve a critical problem like malaria diagnosis,” Prakash explains, “we needed to design a human-powered centrifuge that costs less than a cup of coffee.”

This is one in a series presenting news on technology and innovation, made possible with generous support from the Lemelson Foundation.