Sea urchins inspired a strong new medical staple

Three teens used the animals’ spines as the idea behind a new way to close wounds — and keep them shut

Watch your step! That’s a sea urchin. Their spines may hurt, but South Korean teens used them as the inspiration for a better way to close wounds.

Peter Southwood/Wikimedia Commons (CC-SA-3.0)

PHOENIX, Ariz. — Sea urchins can be a pain in the, er, foot. These round critters are coated in defensive spikes. When a bigger animal tries a mouthful — or an unsuspecting human takes an unlucky step — they quickly realize their mistake. The urchin’s spines sink in and are notoriously difficult to get out. But three teens saw this animal’s protective technology as something that could aid medicine. They used it to design a way to staple wounds shut.

Sometimes, doctors and nurses will close a big cut with stitches or glue. But other times, they turn to staples. Surgeons can put them in quickly. And wounds that are stapled shut can heal faster than those closed with stitches. But no medical device is perfect. Chae Ryeon Lee, 17, learned that staples could fall out, leaving wounds vulnerable to infection. That inspired the 10th grade student at Incheon Posco Academy in South Korea to start a project with her school science club to redesign medical staples.

At the same time, fellow club member Esther Ji Young Lee, 16 — a junior at the school — was learning about sea urchins. She saw a video about how their spines didn’t come out easily. Curious, she wanted to learn more about them. Esther and Chae began sharing ideas. With the help of Jaewoo Song, 16, and other members of the science club, the teens decided to see if sea urchin spines might offer clues to the design of better sutures.

They started by looking closely at sea urchin spines.

“I tried to use a microscope at school,” Esther says. But no matter how hard she tried, she couldn’t see the spines in enough detail. Her team eventually got to use a scanning electron microscope, or SEM, at Yonsei University in Seoul. This instrument scans the surface of a specimen with electrons. Those that bounce off the object form an image. The SEM imagery brought the urchin spines into crisp detail. Each, they found, had many tiny barbs branching off it. Once the spine was in someone’s foot, those barbs would all but lock the spine in place.

That inspired the teens to put similar backward-facing barbs into their staples. It would let them hook into skin and stay there.

Printing for points

The design wasn’t simple, Chae explains. The students had to figure out what the best barb structure would be. They also had to decide how many barbs to put on the staple’s shaft and what angle from that shaft would best anchor them into tissue.

At first, the team tried to make a model of their staple by cutting off the tips of plastic pipettes — fluid collection tools — by hand. But they couldn’t design their model in enough detail.

Then Jaewoo began working with a 3-D printer — a printer that lays down layers of plastic to build an object. But the 3-D printer couldn’t print staples tiny enough to work. The team compromised with a model of what they wanted, one that was about five times larger than the staples they eventually hoped to make.

They built some of their models with two barbs. Others had three. They tried wide barbs on the end. They also tried narrow barbs pointing backward, like arrowheads. Each time, they investigated how much force it took to tear their “staples” out of some artificial skin that they had purchased online.

They didn’t have a scientific tool to measure their pulling force. So they made one out of a pulley in the ceiling of their school and a force meter. It took 3.9 newtons to yank out a normal medical staple, they found. Adding barbs increased the force needed to remove the staples. If the barbs stuck out a little — at an angle of 20 degrees from the staple — they were even harder to yank free of the skin.

Their best sea-urchin-inspired staple had three extra barbs along its length. Each barb pointed exactly 20 degrees out from the staple. This design required 11.8 newtons of force to yank out of their artificial skin.

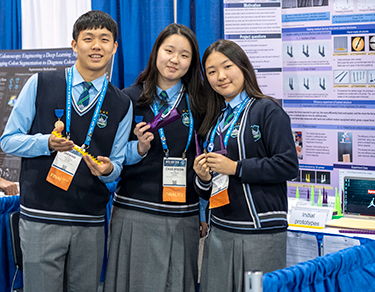

The teens brought their 3-D printed staples to the Intel International Science and Engineering Fair. This competition was created in 1950 by Society for Science & the Public, which still runs ISEF. (The Society also publishes Science News for Students.) This year’s fair, which was sponsored by Intel, brought more than 1,800 students to Phoenix from 80 countries.

For this year’s project, the Korean teens focused on the physical parts of the sea urchin barb, Jaewoo explains. But they aren’t done. Now, he says, they want to focus on the chemical aspects. After all, if a staple sticks in really well, getting it out could be a real pain. The team hopes to design a staple that will eventually dissolve in place once the wound is healed. If it works, that nasty sea urchin sting might one day end up inspiring something that saves patients a lot of pain.