Teen invents a dip to keep germs away

Her eco-friendly chemical dip for fabrics and more could halt bacterial growth

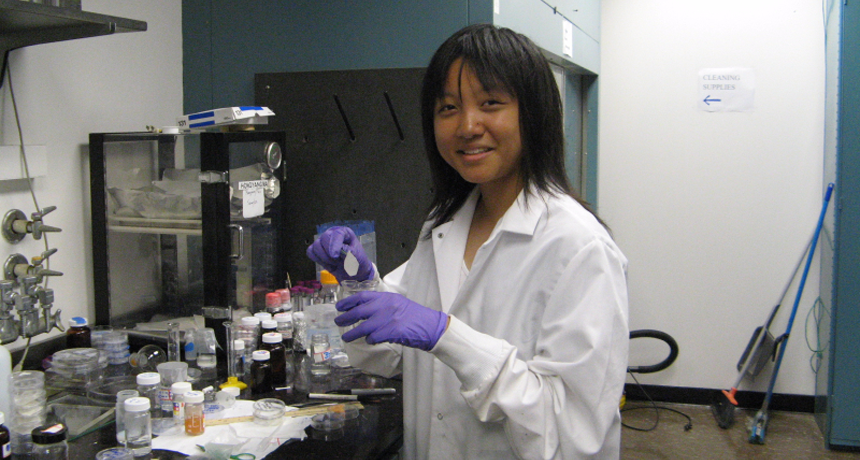

Jessica Tian, 17, created a chemical dip to keep treated paper, fabrics and more free of harmful bacteria.

J. Tian

WASHINGTON, D.C. — Our lives are bursting with bacteria. The bugs are inside our bodies, on our skin and on most surfaces we touch. That’s not necessarily a bad thing. But some places need to be bacteria-free, such as bandages for wounds or food packaging. Jessica Tian, 17, has come up with a way to keep bacteria away. She created germ-free papers by dunking them in a special chemical bath.

The senior at Del Norte High School in San Diego, Calif., showed off her method at the Regeneron Science Talent Search. The science competition is run by Society for Science & the Public. It is sponsored by Regeneron, a company that designs and makes medicines. The event brings together high school students each year to share their science projects with the public. The 40 finalists also compete for cash awards totaling almost $2 million. (Society for Science & the Public also publishes Science News for Students and this blog.)

Jessica’s chemical bath was developed to leave a germ-killing coating on cellulose. The outer wall of plant cells contain cellulose. But that’s not all. “Cellulose is versatile,” Jessica explains. “It’s in our clothing, in food packaging, in pretty much every aspect of our daily life.”

Each molecule of cellulose is a long chain built from sugars. These chains bond easily with water. That’s good; it helps paper towels soak up spills. But this is also why wet cellulose is a great home for bacteria. And some of those germs may pose a risk to health. That’s especially true when they grow on a bandage or food wrapper. Scientists have been trying to invent antimicrobial coatings to stop bacteria from sticking to cellulose. However, Jessica notes, “most methods require heat and pressure. And some lead to air pollution.”

“I wanted to create a method that could [add] antibacterial properties to cellulose in a simple way,” the teen says. She wanted it to be inexpensive. It also had to be easy to apply on a large scale and pose little risk to the environment.

To figure out how to do this, Jessica traveled across the country to spend a summer in the lab of Benjamin Hsaio. He’s a chemist at Stony Brook University in New York. The Simons Summer Research Program for high school juniors connected Jessica with Hsaio. “This was the first time I got to work in a lab,” she says. “I really enjoyed the whole atmosphere.”

The teen worked to add titanium dioxide and silver nanoparticles to cellulose paper. Titanium dioxide is a white pigment. When exposed to ultraviolet light, the negatively charged electrons in it can become excited. The titanium oxide then breaks down water. This produces free radicals. These are charged molecules that can attack and kill bacteria cells.

Usually, Jessica says, titanium dioxide requires a lot of energy to activate its germ-killing prowess. She thought she saw a way to lower the energy needed, though: add silver nanoparticles. These are tiny particles of silver that are only billionths of a meter in diameter. They reduce the energy needed to excite the electrons in titanium dioxide. Adding an ingredient, this way, is known as “doping.” The doped silver should let titanium dioxide kill bacteria using only light from the sun, Jessica hypothesized.

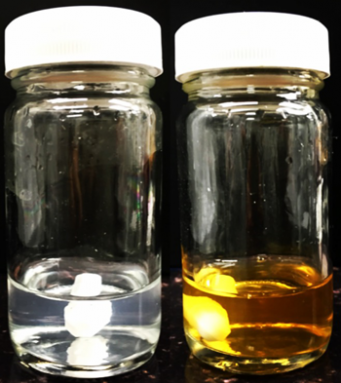

In the lab, Jessica created a colloid (KOLL-oid) solution. Tiny particles of titanium dioxide and silver nanoparticles were spread fairly evenly throughout the liquid. She created three versions. Each had different amounts of titanium dioxide and silver. Then the teen dipped cellulose papers into one of the solutions and dried them in an oven. Other papers were covered in titanium dioxide alone or nothing at all. These served as controls.

Once the papers were dry, Jessica dipped them in solutions of bacteria. Then she rubbed the papers onto lab plates containing agar — a gel containing the nutrients needed for bacteria to grow. After 24 hours, she checked the plates.

The titanium dioxide and silver colloid had killed 99 percent of the bacteria, compared with untreated cellulose. The coating of titanium dioxide alone did not work as well.

“I knew that silver and titanium dioxide could work together,” Jessica says. There had been a lot of research on silver and an titanium dioxide, she notes, “but not much on both of them together [on] cellulose.”

The best part, Jessica says, is that her treatment poses no threat to the environment. Other methods need high temperatures or pressures to create a germ-killing coating. All Jessica’s needed was a slow dip in the chemical bath. The simple, low-cost coating “could be applied to clothing so it could have antibacterial properties,” she says. “I think it could be applied even in developing countries.”

For now, she’s only applied her mix to small bits of cellulose paper. But if the dip works on clothing, bandages or paper, it could help keep them germfree when they need to be.

Follow Eureka! Lab on Twitter