Teen prints a device to help keep wounds dry

Made of carbon particles printed on paper, sensor detects when a bandage gets wet

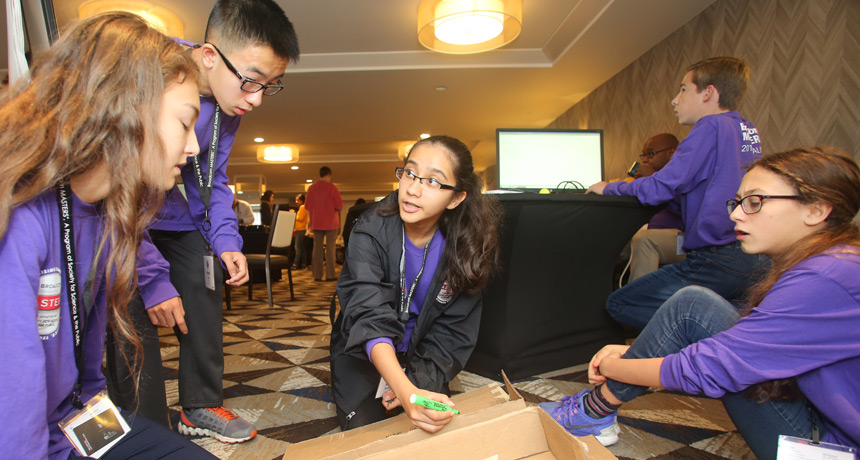

Anushka Naiknaware (center) works on a project with other members of her team at the 2016 Broadcom MASTERS. Team members from left: Rachel Pizzolato, Nathan Deng, Lucas Ritzdorf and Aria Eppinger.

L. Doane/SSP

WASHINGTON, D.C. — When you get a cut or blister, you cover it with a bandage. How do you know when to change it? Maybe you just wait until it’s wet or dirty. But when people have long-term — or chronic — wounds that take months to heal, changing bandages too early or too late could make healing take even longer. When Anushka Naiknaware, 13, learned about chronic wounds, she decided to make a device that could alert a person when it’s time to change their bandage. Her invention required tiny particles of carbon, a smartphone — and her home printer.

Anushka is a student at Stoller Middle School in Portland, Ore. Her invention brought her to the 2016 Broadcom MASTERS competition, where she won first place in mathematics. MASTERS stands for Math, Applied Science, Technology and Engineering for Rising Stars. Created by Society for Science & the Public and sponsored by the Broadcom Foundation, the yearly event brings 30 middle-school students together from around the country to show off their award-winning science fair projects. (Society for Science & the Public also publishes Science News for Students and this blog.)

Chronic wounds are wounds such as ulcers — or open sores — that take longer than three months to heal. These wounds are common in people who are older or who have certain conditions, such as diabetes. Chronic wounds affect around 6.5 million people per year in the United States. With so many people suffering from them, Anushka wondered, “what is this…and why has no one addressed it yet?”

Changing the dressing on a wound too often can provide an opportunity for infections to sneak in. But if a bandage gets very moist very quickly from the inside, it might be filling with pus — a sign an infection has begun. Judging just when to change a bandage is important. Anushka decided to develop a device to guide this timing.

The invention needed to be sensitive to moisture — but not too sensitive. It had to be something that wouldn’t irritate the wound or the person’s skin. And it should probably be cheap.

After a lot of trial and error, the teen settled on a design that used an “ink” filled with carbon nanoparticles. These are tiny spheres of carbon atoms. They are conductive — they allow an electric current to flow. And when they are printed onto paper in a line and connected at each end with copper wires, electricity from a battery can flow along the line from wire to wire. But this flow changes when the nanoparticles get wet.

Anushka made an artificial “pus” out of acetic acid and water, and dripped it on some nanoparticles. She found the pus increased resistance. The electricity could not flow as well.

To get the carbon nanoparticles into a bandage, the teen mixed them into an ink to print onto paper. But first, she treated the paper with a chemical called chitosan. Chitosan is a chemical from the shells of shrimp. It prevents bacteria from growing and helps to stop bleeding. It is added to some bandages to help blood clot faster.

The teen loaded her ink into a printer cartridge to print onto her special paper. Well, actually, Anushka loaded her ink into many, many printer cartridges. Just changing a printer cartridge isn’t easy, and filling one is even harder. “Messy is an understatement,” she says. “I’ve jammed printers. I’ve jammed ink cartridges.… I did all this at home. My carpet used to be white. Now it’s stained gray from carbon nanoparticles.”

Anushka hooked up the printed carbon nanoparticle patterns and copper wires to a Bluetooth sensor. The sensor measured resistance and could transmit the information over short distances. She then placed the sensor inside a bandage. If moisture within the bandage gets too high, and resistance goes up, an alert goes off. The teen designed two versions — one that lights up a tiny light, and another that sends an alert to a smartphone.

The small printed papers cost only five to 10 cents, Anushka estimates. The Bluetooth sensor is more expensive, but the teen notes that it could be used over and over again. She also knows there’s a long way to go before her design can help patients. It hasn’t even been tested on a real person yet. “You have to make sure everything works perfectly,” she says. “I want to see this project to the end, but there’s a lot of intervening work that has to be done.”

Follow Eureka! Lab on Twitter