‘Print’ almost anything

3-D printers allow people to build almost anything they can imagine — from toys to food, buildings to body parts

Scientists at Cornell University used a 3-D printer loaded with cheese “ink” to print a tiny, edible space shuttle.

Creative Machines Lab (Cornell Univ.)/French Culinary Institute

Imagine having a printer hooked up to your computer that could make anything. Tired of your toothbrush? No problem. Print a new one. Want a chocolate treat? Print it. Need a new dress, new shoes or maybe just new cleats for soccer? Just choose a style and size. Then print, print and print some more.

And why stop there? You might print a fake dinosaur bone. You might also print out a life-size copy of your own head. You could print another printer for a friend. And if your printer was big enough, it could print out the body of a car or even a new house.

No one machine can make all of these things, but three-dimensional printers are getting very close. Engineers have printed every single thing listed above — except the house. (And architects plan to knock that one out by the end of 2013.)

Traditional printers work by putting ink (or toner) on paper. Not 3-D printers. They work with plastic, metal, ceramic or other materials, including food. The printers lay down these novel “inks,” thin layer after thin layer, starting from the bottom up. Eventually a solid object emerges. 3-D printing is an exciting, new technology. It is also taking the manufacturing world by storm.

Dawn of a new technology

Until recently, 3-D printers were so expensive that only large companies could afford them. In just the last year or two, their cost has dropped dramatically. Today, you can buy a 3-D printer for as little as $300. The technology offers the potential to print anything at home, when you want it, without having to buy it in a store or order it from a factory.

Of course, there’s a catch. It has to do with the word “potential.”

Not all 3-D printers are created equal. Low-cost models cannot always make high-quality objects. They may not be very precise, and they run on cheaper materials, such as plastic (and sometimes food, but more about that later). More expensive printers may use exotic metal or ceramic powders.

The more affordable printers “are not the greatest printers ever. Some of them are not even reliable,” says Jennifer Lewis. An engineer at Harvard University, Lewis has led the development of new kinds of materials that can be used as ink in 3-D printers.

Even the sometimes poor quality of low-cost printers may change, and soon. 3-D printing for the do-it-yourself community is just getting started, Lewis points out. The technology has a long way to grow, as did personal computers when they debuted 40 years ago.

“When desktop computers first came out, they couldn’t do very much,” Lewis says. Now, even an inexpensive desktop computer can be as powerful as the first supercomputers.

Computing power has made 3-D printing possible. A person with an idea can easily design a 3-D object using computer software, or even from a digital copy of an existing object with a 3-D scanner. The process is fairly easy. And that is why 3-D printing could drastically change the world of manufacturing a few years from now.

Already, creative people around the world — known as “makers” — have formed virtual communities around 3-D printing. They share design ideas over the Internet, swap files and even improve upon each other’s work. Together, these makers are generating ideas (and real objects) that would have been hard to imagine even a few years ago.

Recent magazine and newspaper articles have called 3-D printing the “next industrial revolution.” Like the original Industrial Revolution that began in the mid-1700s, this modern revolution could lead to major changes in how things are made. In fact, in his 2013 State of the Union address, President Barack Obama said 3-D printing “has the potential to revolutionize the way we make almost everything.”

Layer by layer

According to legend, the French sculptor Auguste Rodin was once asked about his work. “I choose a block of marble and chop off whatever I don’t need,” he replied. In other words, he used subtraction to create. 3-D printing is the opposite: It’s all about addition.

To understand how 3-D printers work, imagine you want to sculpt a loaf of bread from clay. Only you don’t just mold a single, large lump of clay into a loaf shape. Instead, you start by shaping a single slice out of clay, and laying it down. Then you form the next slice — and place it on top. Keep going until you have a neat stack of thin layers of clay that together resemble a bread loaf, standing on end.

That is sort of the idea behind 3-D printers. Except machines print and assemble the object. A person’s job is to use computer software to describe the thing she wants the printer to print.

This blueprint includes the size and shape (and sometimes color) of the object. Next, a computer program digitally “slices” the object described in that file, chopping it up into layers. It then feeds that information to the printer, and the printer tackles each layer, one by one.

The printer moves back and forth, side to side and up and down. A small nozzle deposits a single, thin layer of heated liquid material that hardens as it cools. (It’s a little like letting wet sand dribble out of your fingers when building a drip castle.) Once the bottom layer is in place and solid, the printer “prints” the next layer on top of it. And so on. Each layer adds to the object. This process gives 3-D printing another name: additive manufacturing.

Key to 3-D printing are the “inks” used — and no, they don’t include bread (though some do use sand). The simplest inks consist of plastics that flow when heated, but harden when cooled. More complex printers use powdered metals or ceramics that can be heated and fused, in a process called sintering. Some scientists are even figuring out how to create biological inks that contain cells. These inks could be used to print new living tissues.

3-D printing can be fun too. For Valentine’s Day this year, a Japanese company used a 3-D printer to make chocolate copies of people’s faces. (Talk about a chocolately chip off the old block!) Meanwhile, researchers at Cornell University in Ithaca, N.Y., have been refining the use of edible inks — liquids made from finely ground foods. For example, they have printed out miniature, gourmet space shuttles using ink made from scallops and cheese. They have also made cookies with secret messages hidden inside.

At the recent Fashion Week in Paris, a yearly fashion event, 3-D printing turned stylish too. A Dutch fashion designer named Iris van Herpen worked with architects and artists to design and print clothes. They included a dress, skirt and cape. The dress is made from plastic fibers fused together with a laser within a 3-D printer. The skirt and cape both combine soft and hard materials, again produced using a 3-D printer. The clothes were made for show, and not necessarily everyday use. But that could soon change. Van Herpen believes “it will only be a matter of time before we see the clothing we wear today produced with this technology.”

3-D printing likely will change the way we think about a lot of things, including weapons. Cody R. Wilson, a law student in Texas, has used 3-D printing to manufacture an important part of a semi-automatic gun. Wilson then shared his plans on the Internet, and more than 10,000 people downloaded them. For now, it’s still cheaper to buy a finished gun from a store. Still, Wilson’s project shows that one day it will be possible to print out an entire weapon at home. Some people worry that the technology could put guns into the hands of criminals. So it is easy to understand how 3-D printing is also controversial.

These organs don’t bleed red ink

These new printers aren’t all about fashion, firearms and food, however. In research laboratories around the world, scientists and engineers are studying ways to use 3-D printing to make things found only in nature.

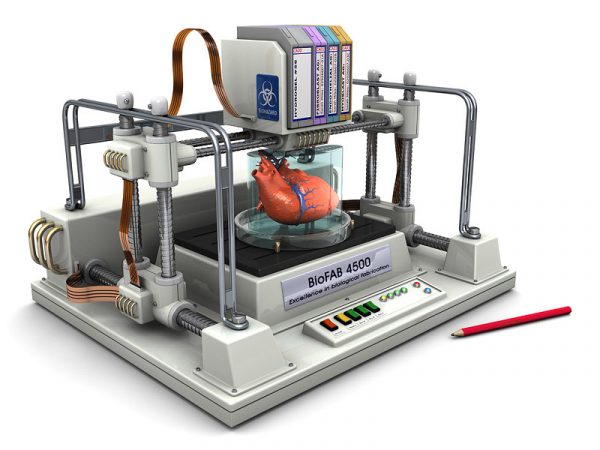

Ibrahim Ozbolat, for instance, wants to print human organs. As a start, he and his collaborators are creating biological “inks” that consist of living cells. Eventually, their goal is to harness a 3-D printer that uses those inks to build a living, functioning body part.

Ozbolat in particular wants to print a new organ that could do the job normally done by the pancreas, the organ that produces insulin. That hormone plays a role in helping the body use blood sugar, an energy source. A person whose pancreas cannot produce enough insulin develops one type of a dangerous disease called diabetes. Ozbolat says that implanting a printed pancreas into people with that type of diabetes might help them produce enough insulin to keep their blood-sugar levels in check.

Printing with cells takes a long time, Ozbolat notes, and “after six or seven hours, the cells can get damaged.” His solution was to design a new type of 3-D printer. One of his students recently built a prototype. The printer has two arms, each with a nozzle-like printer head at its end that acts like a separate device. Ozbolat’s printable pancreas isn’t ready yet, but his custom printer is a step in the right direction.

“We are trying to construct the organ-like structure using two printers,” Ozbolat explains. As one arm lays down the cells to build the pancreas, the other installs blood vessels. Those vessels can deliver oxygen and nutrients to the newly printed cells, keeping them alive during the printing process. This way, layer by layer, Ozbolat hopes to build a living organ.

A printed pancreas is just the beginning. If Ozbolat’s idea works, he imagines moving on to building more complicated organs — such as living, breathing lungs or even a beating heart. Right now, if transplant patients need a new lung, heart or other vital organ, they must wait for a donor to become available. Unfortunately, that usually happens only when someone dies. In the future, 3-D printing may eliminate such ghoulish waits. A biomedical engineer might simply tweak the computer file to match a patient’s need, and then click “print.”

Call it III-D

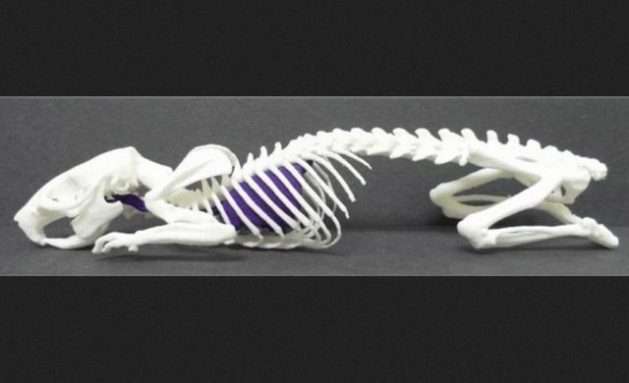

Using 3-D printing to copy human tissue can even help other areas of science, including archaeology. Earlier this year, researchers in the United Kingdom used the technology to help solve the mystery of a king’s death many centuries ago.

Digging beneath a parking lot, scientists from the University of Leicester in England recently discovered the remains of King Richard III, who had ruled over England for two years in the 15th century.

This past February, scientists at Loughborough University, also in England, scanned the king’s skull and then used a 3-D printer to create a plastic replica. Once fully assembled, the skull showed the battle wounds that probably ended the monarch’s life in 1485.

Richard Harris, an expert in 3-D printing at Loughborough University, led the project. The researchers’ first step was to create a virtual 3-D computer model. Later, as a 3-D printer began its work, “seeing the skull of Richard III emerge … was incredible,” Harris says.

Copies of the skull could be studied by other researchers or displayed in museums for a long time to come.

The future

For now, 3-D printing is still in its infancy. But it has the potential to mature very quickly.

As exciting as today’s projects are, they may pale in comparison to those on the horizon — and beyond.

Perhaps the most radical idea is to take 3-D printing to space. In February, the European Space Agency (ESA) announced it was teaming up with architects to design a printed moon base. The idea is to send a large 3-D printer to the moon. Once there, it would use lunar soil and other ingredients for ink. This “ink” would be laid over an inflatable dome — building a stony covering, layer by layer.

NASA, the American space agency, is also interested in 3-D printing, and not just for bases on the moon, but also for those on Mars and asteroids too.

Imagine life on such a base. Astronauts could print their own meals, clothes and tools. They could print replacement parts for their spacecraft or even all the components needed to build a brand-new rover.

These futuristic scenarios, right now, are ideas communicated using words. While traditional printers can put those words on paper, 3-D printers can turn those ideas into reality. And as these machines grow in sophistication (and shrink in price), they will allow many more people to realize ever more complicated ideas.

So what’s yours?

Power Words

cell The smallest structural and functional unit of an organism, typically too small to see with the human eye.

technology The application of scientific knowledge for practical purposes, especially to create products or industrial processes.

laser A device that generates an intense beam of single-colored light. Lasers are used in drilling and cutting, alignment and guidance — even in surgery.

sintering Using heat to turn a powdered material into a solid.

biology The study of living things.

manufacturing The making of things, usually on a large scale.

engineering The use of math and science to solve practical problems.